by Jeff Schnabel, CUI Inc.

DOE power supply efficiency specifications target a broader array of power supplies to save energy and reduce greenhouse-gas emissions.

Market enthusiasm for new high-tech devices is undiminished. The Consumer Electronics Association, in its July 2015 U.S. Consumer Electronics Sales and Forecasts report, predicted a total industry revenue rise of 2.4% to $285B. Major contributors include continued growth in smartphone and notebook/netbook sales and new categories giving buyers more reasons to spend. These include 4K ultra-high-definition televisions, connected-home technologies and wearable devices.

On the other hand, governments are trying to limit demand for electrical energy, both to ensure grid stability and to combat climate change. As sales of high-volume consumer electronics continue rising, the resulting squeeze on resources force greater energy efficiency measures. A key concern has been the energy wasted when electrical devices are in standby modes. In 1998, this was estimated at about 5% of all electricity generated.

Eco-design initiatives, such as Energy Star in the U.S. and ErP in the E.U., have evolved to limit both the active and standby power of equipment such as televisions, set-top boxes, computers and domestic appliances. The external power adapters of equipment such as notebook computers and office machinery have also come under scrutiny. In 2004, California became the first authority to introduce mandatory specifications to reduce the energy dissipated by external power supplies.

Today, the International Energy Efficiency Marking Protocol for External Power Supplies is the globally accepted framework setting out limits on standby consumption and average efficiency for such adapters. Within this framework, the latest specification is Level VI, which was introduced by the U.S. Dept. of Energy (DOE) on February 10, 2016. This requires any external power supply manufactured after this date and shipped into the U.S. to meet new efficiency targets. DOE estimates this more rigorous standard will save 47 million tons of CO2 emissions annually.

New specification, tougher targets

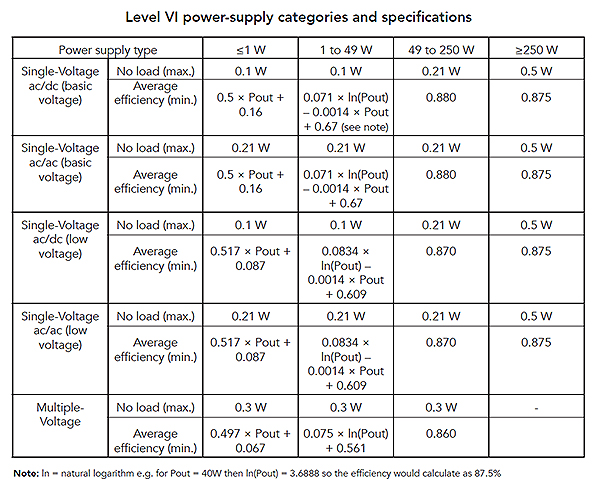

The new Level VI specifications demand higher average efficiency and lower no-load power consumption compared to current Level V power supplies. The new Level VI specification is also significantly more complex than previous versions. Several categories of power supplies are now defined, and new classifications will be regulated for the first time. Some of the newly regulated products include multi-voltage power supplies as well as single-voltage power supplies over 250 W. By including these high-power adapters, Level VI will have a significant impact in markets for industrial equipment not previously covered by the marking protocol.

Examples of basic single-voltage supplies include those used by routers, set-top boxes, portable industrial devices and other consumer electronic devices in the 1 to 49-W power range. Telecommunication network infrastructure equipment, appliances and office equipment are typical applications in the 49 to 250-W range while industrial devices featuring motors or lasers will be covered by the above-250-W category.

Required efficiency levels for several categories spelled out in the Level VI standard are specified as a calculation involving supply output power. Cranking through a few of these calculations for basic and low-voltage supplies reveals that the standard’s distinction between basic- and low-voltage appears to apply a less stringent requirement for low-voltage supplies. This certainly helps ensure the manufacture of such supplies is economically viable in the more price sensitive market for consumer products and home automation devices that fall into this category. Similarly, running the standard’s efficiency calculation reveals the ≤1-W category appears to have a relatively undemanding efficiency specification of 66% or less. But currently, external adapters at these low power levels are rare.

The new specification also introduces a distinction between direct operation and indirect operation. It applies only to units intended for direct operation. Direct power supplies are defined as being able to function in the end product without a battery. An indirect power supply is not a battery charger, but cannot operate the end product without the assistance of a battery.

Some classes of direct power supplies are exempt from the need to comply with Level VI. These include devices that require FDA approval as a medical device in accordance with section 360c of title 21, and ac/dc power supplies with nameplate output voltage less than 3 V and nameplate output current greater than or equal to 1,000 mA that charges the battery of a product that is fully or primarily motor operated.

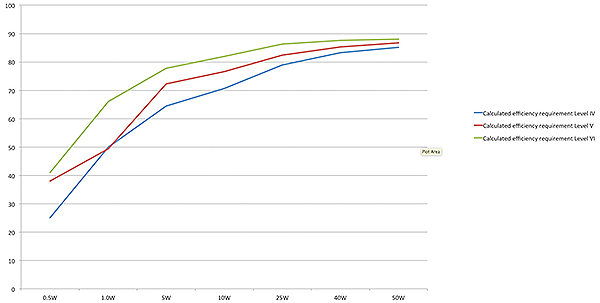

A plot of efficiency levels versus power supply output shows how the Level VI average efficiency specification for power supplies stacks up against earlier Level IV and Level V specifications.

Changes under the skin

Power supply makers have generally found that Level VI efficiency levels couldn’t be met with the same supply designs used for Level V or earlier designs. So new topologies have generally been necessary to handle the more stringent efficiency demands. For example, CUI anticipated the new Level VI regulations by introducing compliant adapters as early as the latter half of 2014. Important design changes were necessary to satisfy the new, stricter targets, based on CUI’s established topologies. For units under 120 W, this is a flyback topology, while adapters over 120 W use an LLC resonant topology.

A comparison of the efficiency of equivalent Level V and Level VI power supplies, measured at 25, 50, 75 and 100% of full load (7.5 V, 4 A) shows that Level VI efficiency improves at all levels, and particularly at lower loads.

To meet the tougher standards, low-voltage/high-current models now feature synchronous rectification in the secondary side. Replacing conventional rectifier diodes with low-RDS(ON) MOSFETs has eliminated diode losses resulting in a net saving when the power to run the associated MOSFET controller IC is taken into account.

The PWM control strategy is significantly different compared to the previous generation. In CUI’s Level V adapters, the main control IC typically operates at a fixed frequency of 65 kHz, but the latest controllers for Level VI units improve efficiency as load drops by reducing the switching frequency to 22 kHz. Improving light-load efficiency is important because the IEC-approved test method for assessing average efficiency (AS/NZS 4665) calls for power to be measured at 25, 50, 75 and 100% of rated load. The arithmetic average of the data from all four points is then calculated to determine overall average efficiency. Because the efficiency at 25% load is the lowest of the four points, improving performance at light load results in better average efficiency.

In addition, the latest controllers draw lower quiescent current than their predecessors. This helps meet the aggressive Level VI no-load targets.

Careful management of power-factor correction (PFC) circuitry is another feature of the new Level VI units. Although PFC is mandatory for power supplies rated at 90 W or over, the circuitry can be disabled at lower loads. This eliminates significant energy losses, thereby helping to improve both the average efficiency and no-load consumption. Ripple noise can be slightly higher when the PFC circuitry is de-activated, but this should not be a problem for most applications.

Despite changes throughout the design, most of the new Level VI units retain the same case sizes and external appearance as the earlier models. On the other hand, greater average efficiency has helped to reduce typical working temperatures, resulting in an improvement in reliability.

Mandatory compliance

The new Level VI efficiency standards for external power supplies are currently only mandatory in the U.S., but in practice it is forcing OEMs worldwide to adjust their purchasing and supply-chain arrangements. In any case, historical patterns suggest that other territories, such as the E.U., are likely to adopt the Level VI specification themselves.

It is usually more economical and straightforward to ship products with the same power supply type to all markets globally, so it makes sense to ensure that all units comply with the highest standard currently in force. This helps to minimize product-management challenges and avoid any potential for costly shipping errors.

Level VI power supplies have been available in the market for over a year now, and OEMs have had every opportunity to prepare for the transition to Level VI. Anyone who is unsure whether the power supplies they are now purchasing are compliant would be well advised to look for the Level VI marking on the label or check with their supplier.

References

More information on the Level VI standard: www.cui.com/efficiencystandards

Is there any danger in using my old laptop AC Adapter (Level V) on a newer laptop?

Thank you for your timely response and your assistance.