New protocols for high connectivity need robust protection for reliability and safety.

James Colby | Littelfuse, Inc.

At the turn of the century, automobiles hosted many electronic systems that were basically independent. Since then, the growth of connectivity and the rise of artificial intelligence and machine learning have changed automotive electronics dramatically. Vehicles of all types are becoming complex interconnected communication centers, and autonomous vehicle functions are only increasing that level of sophistication.

New protocols are being deployed to boost connectivity while facilitating broadband-like automobile communications. V2X technology is designed to help vehicles communicate with the road to prevent collisions and optimize traffic flow. Automotive versions of Ethernet and HDBaseT are being implemented to boost the speed and efficiency of high-speed data transmission between key subsystems such as high-definition cameras, Lidar and radar sensors, and wireless connectivity features.

Better connectivity makes automobiles safer and more versatile, but it also presents numerous technical challenges to engineers designing them. The more advanced automotive chipsets must also become smaller and denser, making them more susceptible to electrostatic discharge (ESD). Design engineers must understand how to protect these chipsets to ensure their reliability.

Highly sensitive chipsets and demands for faster data require exceptional ESD protection for automotive modules that will utilize these new protocols. Low-capacitance, low-clamping ESD protection devices in compact packages can help make advanced automobile operation safe, reliable, and efficient.

To provide the engineering community with a uniform and repeatable plan for ESD mitigation, the ISO 10605 document was created. The severity of the ISO 10605 ESD pulses is enough to ensure that chipsets will be hard-pressed to survive direct hits.

To create robust, reliable designs, engineers should consider ESD protection solutions early in the design process. In addition, engineers should review and understand the system-level ESD testing required for these modules.

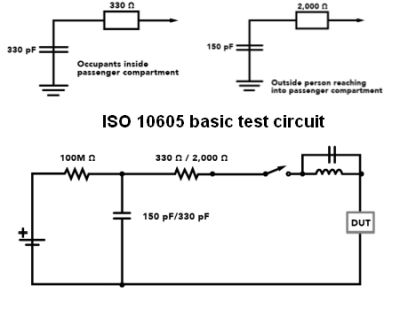

ISO 10605 simulates the discharge of a human body inside or outside a vehicle. It specifically covers ESD in assembly, ESD caused by service staff, and ESD caused by passengers. ISO 10605 is partly

based on IEC 61000-4-2, a standard for system-level ESD immunity. However, it has several key provisions specific to automotive uses. For one thing, ISO 10605 does not define a specific upper limit of stress voltage. The test voltages range between 2 kV to 15 kV for direct-contact discharge and 15 kV to 25 kV for discharge through an air gap. Moreover, some automotive manufacturers have devised their ESD stress levels — some parts can have specifications as high as 30 kV contact and 30 kV air gap discharge.

ISO 10605 testing uses two different resistors, 2 kΩ, and 330 Ω, to simulate different types of ESD events. The 2-kΩ resistor represents a human body discharging directly through the skin, while the 330-Ω resistor simulates a human body discharging through a metallic object. The test also takes place at two different capacitances: 150 pF and 330 pF. These values represent a human body inside and outside the vehicle, respectively. The 330 pF and 330 Ω test is the highest energy/current of any of the ISO 10605 test parameters and thus is the most widely used test standard.

Makers of ESD protection solutions design parts specifically to handle specialized automotive modules. It may be useful to consider a few examples.

Connected vehicles will carry Vehicle-to-vehicle (V2V) and Vehicle-to-infrastructure (V2I) communication modules that allow the vehicle to perform such tasks as making dynamic calculations based on the velocities and locations of other vehicles. Among the aims of the technology is to prevent vehicles from hitting other vehicles or pedestrians, to smooth traffic flows and speed the hunt for parking spots, and perhaps to foster location-based advertising and promotion. The U.S. DoT thinks V2V communications could prevent up to 79% of vehicle crashes.

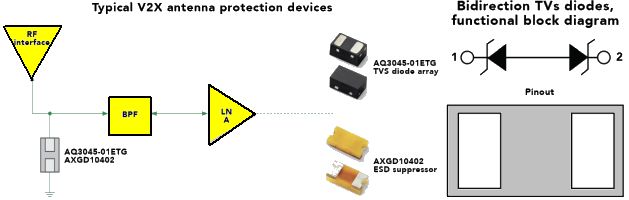

Typical ESD protection devices for V2X modules are designed to suppress fast-rising ESD transients up to 30 kV while adding virtually no capacitance to the circuit, which is important for maintaining signal integrity on the kind of high-speed comm lines that increasingly characterize automotive connectivity uses. These bi-directional surface-mount polymeric devices, going by the trade names PulseGuard or Xtreme-Guard, are designed to conduct quickly enough and at a voltage low enough to prevent damage to protected parts.

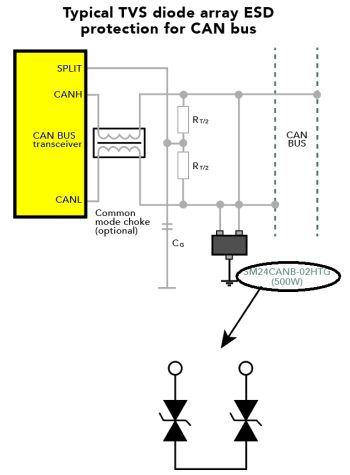

TVS diodes are also designed to work in high-speed Ethernet networks now being optimized for use in automotive environments. High-speed Ethernet will allow multiple in-vehicle systems, such as infotainment and automated driver assistance, to simultaneously access high-bandwidth data throughput over a single, unshielded twisted pair cable.

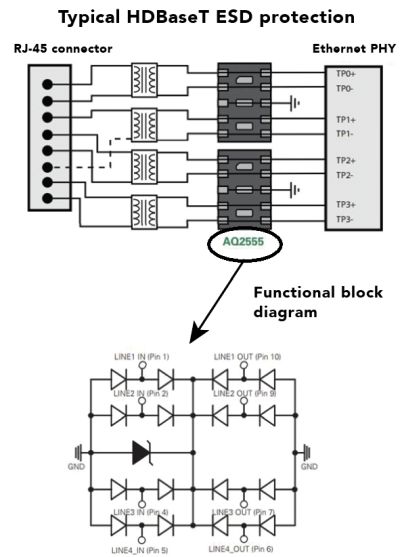

Automotive Ethernet enables 100 and 1,000 Mbps communication using only two communication lines. Similar to Ethernet, HDBaseT has a pathway to connect ADAS, telematics, A/V, and display applications. Providing throughput speeds of up to 2 Gbps, HDBaseT can also move data up to 15 m (50 ft) with no loss of data integrity. The protocol can also tunnel multiple data types, including audio/video, USB/PCIe, Ethernet, control signals, and even power on the same data pair.

Looking down the road, HDBaseT will provide higher throughputs to allow it also to be considered as a data backbone. Expectations are it will eventually handle 4, 8, 12, and 16-Gbps speeds. Highly sensitive chipsets and demands for faster data will require exceptional ESD protection. Low-capacitance, low-clamping ESD protection devices in compact packages will help make advanced automobile operation safe, reliable, and efficient.

References

Littelfuse Inc. | automotive applications guide

The rather important reality to keep in mind is that for the computer driven vehicles the systems are Life Critical, which places some rather extreme demands on reliability and accuracy. Unfortunately it also places a rather large amount of liability with those who represent that their products are adequate for the tsk of protecting these systems. These financial liabilities should be considered prior to making claims that a product is adequate for the task.