In recent years, with higher requirements for the production and manufacturing of new energy vehicles and increasing demand for safer drive batteries, high-performance drive battery BMS has been valued highly and its market share has grown sharply. According to statistics, the market size of BMS in China reached 9.7 billion yuan in 2020, with a year-on-year growth of 6.6%, and it is expected to surpass 12 billion yuan in 2022 and 16 billion Yuan in 2025.

It is generally known that lithium-ion batteries contain highly active lithium. Its internal structure may be damaged by over-charging, over-discharging, or charging and discharging with excessive current, thus affecting service life and performance for a single lithium battery with a limited capacity and density. Besides, the activity of lithium ions and the safety of lithium batteries are also affected when the operating temperature is too high or too low, resulting in the lithium battery burning and exploding in the worst case. Therefore, the smart BMS protection board, a set of safety protection devices, is designed in the lithium battery circuit to ensure battery safety, prolong service life and give full play to the superior performance of lithium batteries.

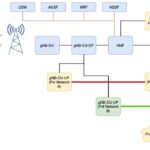

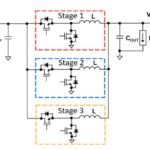

The smart BMS protection board is specially designed for large-capacity series lithium battery packs, with voltage acquisition, active high current equalization, overcharging, over-discharging, over-current, and over-temperature protection functions. It is generally composed of MCU, analog front-end (AFE), memory, and other peripheral electronics, where the MCU serves as the control core of the BMS protection board.

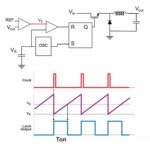

ARTERY AT32 MCUs consist of Cortex-M4 processor core, support CAN*2, RS-485, UART, and other peripheral interfaces to realize multiple communication modes, and process data according to the configuration files of battery packs to make appropriate decisions. During the charging and discharging process, AT32 MCU collects the terminal voltage, temperature, charging/discharging current and total voltage of each cell in the battery pack in real time to protect the battery from over-charging and over-discharging and prolong its service life. When fully charged, it can ensure power balance current between single cells (ternary lithium /lithium-iron: 30±5 mA, LTO: 20±5 mA), realize equalized charging of cells in the battery pack, and greatly improve the charging effect in the series charging mode.

Featured with high performance, high stability, high-cost performance, and low power consumption, ARTERY AT32 MCUs have been put into mass production and widely applied in smart BMS protection boards. The BMS protection boards based on ARTERY AT32F421 and AT32F413 series MCUs have been widely used in electric two-wheeled/three-wheeled vehicles, industrial UAVs, storage AGVs, energy storage for RVs, marine equipment, outdoor portable energy storage, household energy storage, commercial cleaning services, low-speed electric vehicles, and other scenarios.

Advantages of ARTERY AT32F413 MCU for Smart BMS Protection Board include: Up to 200 MHz CPU and 256 KB Flash, meeting LED/LCD display requirements; On-chip integrated CAN*2, RS-485, UART, and other peripheral interfaces to realize multiple communication modes; CAN connected to an electric vehicle control unit to improve system stability and data transfer rate; I2C, connected to AFE for parameter configuration and data acquisition in real time; Rapid ADC conversion rate, to get the battery voltage, current and temperature in time and properly handle relevant issues to prevent over-charging, over-discharging and over-temperature; Operating temperature range of -40~105°C, suitable for complex environment and guaranteeing system stability; Support sLib (security library) to protect core codes.

Leave a Reply