by Koji Ikeda, Sanken Electric Co. and K.C. Nishio, Allegro Micro Systems

Over-temperature can be a problem in high-performance switching supplies. New power rectifier diodes build in safeguards to head off heat build-up.

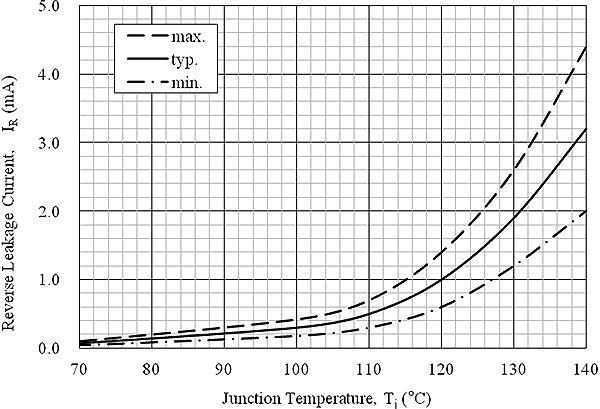

Pulse-width-modulated converter and amplifier designs tend to spend much of their time handling significant levels of electrical current. High currents tend to heat up the power semiconductors used in these circuits. Of course, temperature affects the operating parameters of these circuit devices. For example, the voltage across a forward-biased silicon diode drops by about 2 mV/°C rise in temperature. When a diode is reverse biased, the saturation current flowing through it is also a function of temperature, approximately doubling for each 10°C rise in temperature.

It can also be hard to predict temperature effects. For example, a physical diode that is reverse biased will have a current variation with temperature less than the values predicted by simple device models because there is a component of reverse-bias current, called a surface leakage current, that flows around the junction rather than through it. It varies with temperature at a slower rate than the reverse-bias current through the junction. A rule of thumb for discrete silicon diodes is that reverse-bias current approximately doubles for each 10°C rise in temperature.

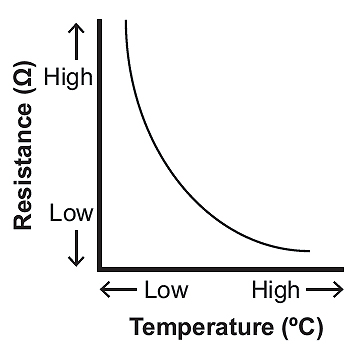

In high-performance switching designs, it is customary to compensate for possible temperature rise and factors affected by it, such as output-voltage error rate. The usual way of adjusting switching circuits for temperature is to add circuitry that reduces current through the diode as temperature rises above a certain point. The typical means of sensing temperature is a thermistor, which is usually situated in the detection circuit. The detection circuit reduces diode current as diode temperature rises above critical levels.

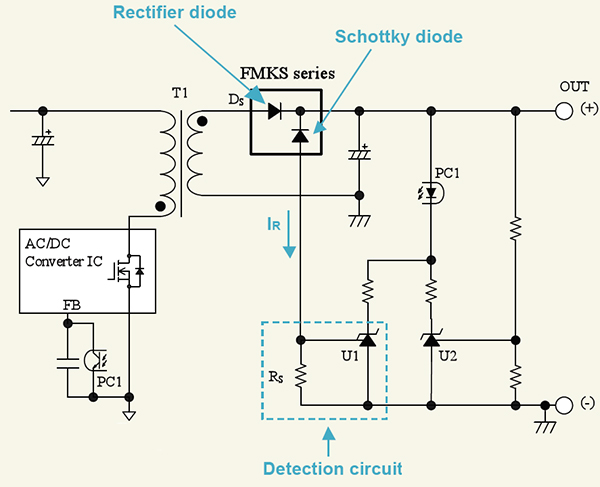

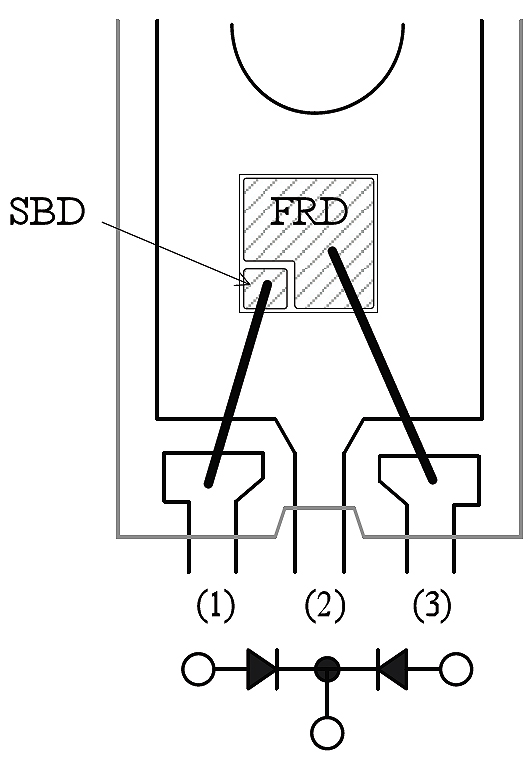

Of course, this kind of compensation works best if the temperature sensor is close to the diode. That is the idea behind new rectifier diodes that feature a Schottky barrier diode formed on the same die as the fast-recovery diode that is used as the secondary-side rectifier diode, making temperature-change detection in real time possible. This technique also reduces part count and design time.

Switched mode power supplies in applications such as audio systems and adapters generally detect an overload in rectifier diodes by monitoring the rectifier diode at the secondary side of the switched mode power supply. In a typical application circuit using an NTC thermistor, the NTC thermistor resistance drops when the temperature of the diode to which it is thermally connected goes up.

Because this temperature sensing circuit resides in the secondary of the power supply, it usually reduces current in the primary side through some kind of isolating element, generally an optocoupler, to avoid any possibility of a primary-secondary short circuit or inadvertent feedback. When the voltage at the REF pin of the shunt regulator reaches the reference voltage, current flows through the optocoupler. The signal sent back to the primary side through the optocoupler is used to limit the supply of electric power. This eliminates the possibility of power supply destruction because of an overload.

When the intent is to put a temperature-sensing element on the same die as the power diode, there are advantages to using a Schottky barrier diode instead of a thermistor. Schottky barrier diodes have a leakage current (IR) that increases when temperature rises. When the temperature of the power diode rises, the leakage current from the Schottky barrier diode (which is thermally connected to it) will increase. The increase of this leakage current boosts the voltage at the REF pin of the shunt regulator.

Thus, in the same way as when using a thermistor, the current flows through an optocoupler. The signal sent back to the primary side through the optocoupler is used to limit the supply of electric power.

In the ideal case, the temperature-detecting device is formed on the same die as the device of which temperature is detected as a means of forming a more intimate thermal connection. An example of the approach is the FMKS series diode, where a Schottky barrier diode is formed on the same die as the fast-recovery diode that is used as the secondary side rectifier diode. Thus, temperature change detection in real time is made possible, with ancillary benefits of lower part count and shorter design time.

Allegro MicroSystems

www.allegromicro.com

FMKS diode info, http://tinyurl.com/z8jy57r

Sanken Electric Co. diode info, http://tinyurl.com/zxdj31b

Leave a Reply