Part 1 of this FAQ looked at the basics of using LEDs in series, parallel, and series/parallel arrays, the implications on the power-sourcing requirements, and the impact of an LED failure. Part 2 looks at other practical issues associated with powering the array.

Q: Given the various configurations, what sort of drive is “best” for the LED array?

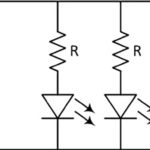

A: The answer is “It depends,” as it usually does. LEDs need to be driven by a defined current, but how to achieve and maintain the current drive depends on the array arrangement and the application.

Q: Should I automatically look for a constant-current (aka current-source) drive?

A: Not necessarily. Vendors of standard power sources for LED arrays offer constant-current (CC) and constant-voltage (CV) sources (drivers). Each can work well if applied correctly. One question is “from what source will I be deriving my current or voltage?” If it is an AC line (120 VAC or 240 VAC) then you have to look at the problem one way; if it is a DC rail, the issue has a different context.

Q: How’s so?

A: With an AC line, you have a large amount of power available, and it is not difficult to develop the needed constant current or voltage from that line, and with high compliance. If you have a DC rail, it may be at a lower voltage, such as 15 V, 24 V or even 48 VDC, so the transformation of the DC voltage into the needed current with the compliance needed become a challenge.

Q: What else?

A: Given the many arrangements for high-count LED arrays, it’s not surprising that there are also many power arrangements, as they are closely linked issues. For example, the design can use one large power supply, or it can use a large supply plus smaller, local voltage or current-output regulators for parallel/serial subsections, down to even one per string. It’s really a matter of cost, failure-mode considerations, commonality of parts, physical arrangement of the LEDs and the supply units, and thermal considerations and heat spreading.

Q: What about using LEDs for area lighting in an office which has standard overhead lighting units, or in home-lighting fixtures?

A: This is an increasingly common objective: using LED-based room and office wide-area lighting and illumination. For home illumination, many vendors of luminaires (the industry term for light fixtures) build AC/DC converters into the luminaire itself, sometimes using multiple, smaller regulators so the space requirements and thermal dissipation can be spread out (unless of the luminaire has a base which can contain the power source).

For office lighting, the major trend is to use LEDs in standard-size troffers (the trade term for the recessed fixtures, Figure 1. Until recently, these usually comprised two or four longer fluorescent light bulbs directly connected to the AC line along with a ballast circuit, but for practical installation reasons, the AC/DC for the LEDs must be located in or near the troffer.

Q: Do I need to design with a constant-current or constant-voltage supply for the troffer?

A: Both are in use, each with pros and cons. The constant-current supply ensures that the source does not deliver more current than the LEDs are specified to handle; this avoids burnout/thermal runaway; also, LEDs are easier to control and dim under constant current, and the light has a more consistent brightness.

However, a constant-voltage source offers certain features, but it must be designed for a specific voltage output, of course, to match the LED arrangement. Constant voltage is a much more familiar technology for the design and installation engineers, and voltage is easier to measure than current. Further, the BOM cost for a constant-voltage system can be lower, especially in larger-scale applications. Constant voltage drivers are most commonly used when the same supply will be used for a variety of different LED arrays, as it allows the luminaire or troffer manufacturer to minimize the inventory of drivers, but the overall assembly tends to be less efficient than a constant-current approach.

Q: This all seems like a lot of work; are there simpler options?

A: Absolutely. Given the desirability of LEDs in many cases and their increasing adoption, vendors now offer LED arrays in standard, preconnected strips, bars, blocks, and other configurations. These modular multi-LED elements are designed to operate directly from a DC rail, with a built-in current-limiting (but power-wasting) resistor, or have a more efficient DC/DC voltage regulator and protection circuitry in each strip. Other LED strips are available for constant-current sourcing. Either way, developing LED-based local and area illumination is becoming more of a “plug and play” situation.

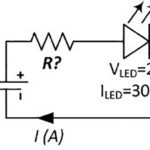

Q: Do I have to figure out how to build a constant current/constant voltage supply?

A: Yes and no. You do have to some work, but recent components such as the LYTSwitch-6 safety-isolated LED-driver IC from Power Integrations make the task easier by supporting both CC and CV designs, Figure 2. This device can be the core or a 65 W CV/CC supply with efficiencies between 85% and 94% depending on load specifics. The data sheet includes a validated reference design which includes BOM, PC board layout, and component mounting details to build a complete circuit. Using this as a starting point brings your specific implementation much closer to regulatory approval with respect to efficiency, power factor, and EMI/RFI mandates.

Leave a Reply