Novel magnetic materials now under investigation could boost power density, lower losses, increase efficiency, and reduce size and cost in power electronics.

One example of what might be possible from such research comes from Southpole Magnetics in Pittsburgh, a company formed by magnetics researchers at Carnegie Mellon University. The firm envisions large-scale, 35-ton transformers redesigned to come in at around 450 lb. The firm thinks such dramatic improvements in magnetic material performance could, among other things, enable more widespread adoption of rooftop solar energy production by commercial enterprises.

This drawback is one of the reasons new magnetic materials are under development that will work from about 20 kHz up into the megahertz range and do so at temperatures up to 300 °C. The high temperature compatibility will be important for inhospitable applications such as electric semitrucks and rooftops in sunny climes of the semitropics.

Additionally, advances in the processing of crystalline soft magnetic steels could also enable rare-earth-free electric machine topologies to match the performance of machine architectures that depend on permanent magnets. Strategies for improved magnetic material performance include nanoscale structure control, novel device geometries, new alloy and compound development, and advanced manufacturing methods.

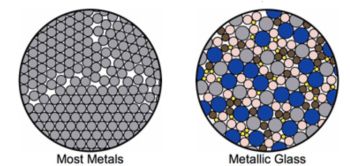

The synthesis of the magnetic material at CMU starts with alloys of iron, cobalt, and nickel that get mixed with glass formers. These constituents are melted in a crucible and cast onto a rotating copper wheel using a technique called planar flow casting. The large thermal mass of the wheel cools the liquid metal at a super-fast rate of about 1 million degrees/sec. The speedy solidification rate prevents atoms from finding positions in a crystalline lattice. The result is a metallic glass whose isotropic structure lets it easily switch magnetization without losing energy.

Of course, there is a big difference between creating samples of metallic glass in a lab and a mass-production process. Currently, the CMU team is working with the National Energy Technology Laboratory (NETL), NASA Glenn Research Center, North Carolina State University, and Eaton Corp. to create high-density transformers.

[…] class of soft magnetic material getting attention is that of amorphous alloys. More specifically, soft magnetic amorphous alloys generally consist of nanograins of ferromagnetic […]