The first race of the new 2016/2017 Formula E season in Hong Kong featured an inverter built with silicon-carbide power semiconductors. The inverter helps power a car raced by the Venturi Formula E team, sponsored by the Japanese semiconductor ROHM.

Formula E, of course, is an open-cockpit race series styled after Formula 1 but using electric motors. The challenge of Formula E is to find the most efficient way of using the energy provided by the battery and applying it on the road. To do this, ROHM developed new power device technology using silicon carbide.

Formula E, of course, is an open-cockpit race series styled after Formula 1 but using electric motors. The challenge of Formula E is to find the most efficient way of using the energy provided by the battery and applying it on the road. To do this, ROHM developed new power device technology using silicon carbide.

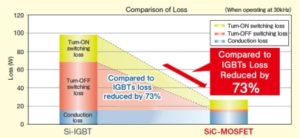

The benefits of employing SiC technology in inverters includes smaller circuitry and less weight, improving weight distribution in motorsports and reducing power consumption in general. SiC devices can also work with higher voltages and currents than ordinary silicon power semiconductors, boosting power density and reducing switching losses even under high temperatures.

The inverter for season three features embedded SiC Schottky diodes, making it 2 kg lighter than the inverter for season two. Electric efficiency has risen by 1.7%, while the volume of heat extraction components has been reduced by 30%. But ROHM says this is just a start. In season four, the SiC MOSFET integrated inverter will demonstrate even better improvements.

The inverter for season three features embedded SiC Schottky diodes, making it 2 kg lighter than the inverter for season two. Electric efficiency has risen by 1.7%, while the volume of heat extraction components has been reduced by 30%. But ROHM says this is just a start. In season four, the SiC MOSFET integrated inverter will demonstrate even better improvements.

ROHM was the first company in the world to manufacture the SiC MOSFET in 2010. In the automotive sector, an increasing number of EVs and inverters are adopting SiC.

In 2013, Venturi Automobiles entered the FIA Formula E series under the Venturi Formula E Team name and became an FIA-approved manufacturer in 2015. Venturi Automobiles supplies full powertrain systems for the Venturi Formula E Team. Venturi Automobiles holds the FIA World Land Speed record for an all-electric vehicle. In 2016, the Venturi Buckeye Bullet 3 set the official top recorded speed achieved by an electrically-driven car of 549 km/h on the Bonneville Salt Flats in Utah.

Leave a Reply