A Stanford-led engineering team has developed a way to not only manage heat but help route it away from delicate devices. Writing in Nature Communications, the researchers describe a nanoscale thermal transistor, something that researchers have been trying to develop for years. Previous thermal transistors proved too big, too slow and not sensitive enough for practical use. The challenge has been finding a nanoscale technology that could toggle on and off repeatedly, have a large hot-to-cool switching contrast and no moving parts.

The thermal transistor design starts with a thin layer of molybdenum disulfide, a semiconducting crystal that is made up of layered sheets of atoms. Just 10 nm thick and effective at room temperatures, this material could be integrated into ordinary semiconductors, a critical factor in making the technology practical.

The researchers bathed the material in a liquid rich with lithium ions. Applying small electrical current forces the lithium atoms to infuse into the layers of the crystal, changing its heat-conducting qualities. As the lithium concentration rises, the thermal transistor switches off i.e. becomes less conductive. Working with researchers at the University of California, Davis, the team discovered this happens because the lithium ions push apart the atoms of the crystal, making it harder for heat to get through.

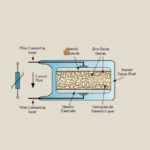

Specifically, the working device is a 10-nm-thick layered MoS2 crystal, prepared on SiO2 (90 nm) on p-type Si. An 80-nm Al layer patterned on top of the MoS2 serves as an electrical contact and as an opto-thermal transducer for measurements. A solid Li pellet acts as the reference and counter electrodes, and 1.0 M LiPF6 in ethylene carbonate/diethyl carbonate is the liquid electrolyte. Researchers were able to modulate thermal conductance reversibly in the device by a factor of nearly 10×, on time scales of minutes.

The researchers envision that thermal transistors connected to computer chips would switch on and off to help limit the heat damage in sensitive electronic devices.

Besides enabling dynamic heat control, the team’s results provide new insights into what causes lithium ion batteries to fail. As the porous materials in a battery are infused with lithium, they impede the flow of heat and can cause temperatures to shoot up. Thinking about this process is crucial to designing safer batteries.

In a more distant future, the researchers imagine that thermal transistors could be arranged in circuits to compute using heat logic, much as semiconductor transistors compute using electricity.

Lithium ARRGH when will we ever learn ? I’ve seen too many accidents with Lithium.

Specialist applications for these devices maybe found with Quantum Computers or Deep Space Electronics – but as Lithium is a toxic substance classified under the Dangerous Goods Act as a high risk material, plus you can’t just dump it at your local tip when it fails – it’s unlikely to ever be practical for domestic applications. Many places you have to pay to dump it, as it needs processing to dispose of.

Also, lithium batteries being temperature and voltage sensitive, catch on fire if not managed correctly, so I see potential fire risks with these when the heat gets excessive because the computer required to control it fails. Just look at the Samsung phones and Tesla cars catching on fire.

Plus there’s the added complexity of a computer operated BMS to stabilize a lithium battery system in order to make it practical. And let’s not talk about the increased cost of Lithium and all the push for people to invest in it, through the share market. Just another money spinner !

More cost – more complexity – more difficulty in keeping stable.

And we call this technology “progress”.

Haven’t they heard of the KISS principle – “Keep It Simple Stupid”. Added complexity is not always considered smart – but rather the opposite.

In the end – there is nothing stating that these transistors are any better than vacuum tubes, other than their small size and possibly being “lighter” than conventional transistors with silicon.

“other than their small size and possibly being “lighter” than conventional transistors with silicon”….

That says it all. Size and weight and compared to vacuum tubes — power consumption — wow. I think that ‘s a LOT. Vacuum tubes are great (I’m a huge fan) when you only need a few. But how about when you need millions or billions? The amount of lithium described in this article is literally tiny, nanometers thin. Is it really a hazard at these levels? The article isn’t about batteries. It’s about a new type of transistor, and incidentally how learnings taken from the development can improve batteries. Might want the read the article before ranting about the dangers of lithium.

Nonsense! why “switch it ON”? why not LEAVE IT ON to dissipate heat? Sounds like hype.