One of the original promises of microelectromechanical systems (MEMS) when they first came along in the 1980s was that they could subminiaturize electromechanical contacts. Built on silicon substrates using the same kind of etching processes employed for conventional ICs, MEMS structures have been used in inkjet printing heads, accelerometers, pressure sensors, and a variety of other areas. But practicality as replacements for conventional mechanical switches has remained elusive. Among the problems: The tiny contacts on MEMS switches couldn’t handle much current. They can also experience arcing and heating that can degrade the lifetime of the switch.

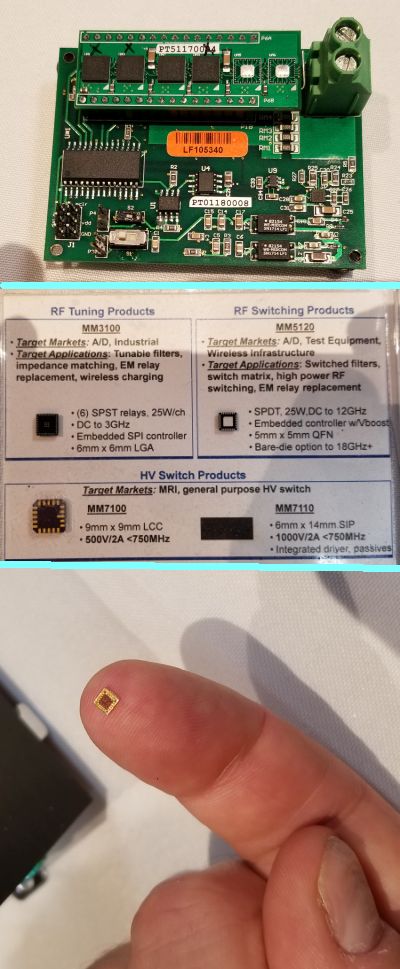

However, these difficulties have been solved, according to Irvine, Calif.-based Menlo Micro, spun off from General Electric research labs. At the recent APEC power electronics conference, Menlo Micro announced a new 200-V/10-A MEMS device called a Digital-Micro-Switch (DMS) Smart Power Relay technology.

“Our DMS technology enables extremely small, lightweight power relays that combine the best features of solid-state and mechanical devices,” noted Menlo Micro SVP of Products Chris Giovanniello.

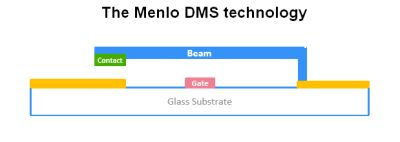

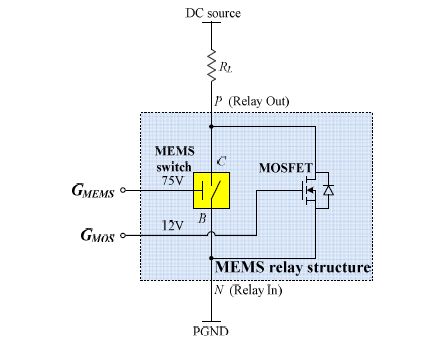

The DMS parallels a MOSFET with the MEMS switch to realize zero-voltage switching. This reduces the switching energy across the contacts which boosts reliability under high voltage and large current scenarios. It also uses proprietary metal processing techniques to increase the reliability of the cantilever beam holding one side of the contact as well as the contact material itself, Giovanniello says. The resulting devices have an operating life exceeding three billion cycles and will eventually hit 20 billion, he says. The fabrication process for a DMS is also relatively simple, consisting of only 12 steps.

Menlo has combined over 200 MEMS high-voltage switches, with fully integrated protection and controls, into a Smart Power Relay evaluation board. The credit-card-sized board is capable of carrying 10 A of dc current, without the need of a heat sink.

One of the applications for the Menlo Micro technology is in high-power, high-reliability RF switches. These are already in applications such as medical instrumentation, test and measurement equipment, and reconfigurable software-defined radios. Typically, these switches are three-terminal devices operating in the 25 to 50-W range. For the Smart Power Relay, Menlo has created a fully isolated four-terminal architecture, complete with advanced features such as over-current protection.

Each metal-to-metal contact in a DMS is smaller than a human

hair, and when combined in massive arrays, the chips can provide extremely low on-state losses (<10 mΩ) in a small package, eliminating the need for large heat sinks. Menlo says its new devices also deliver a 1000x improvement in switching speed over traditional electromechanical relays.

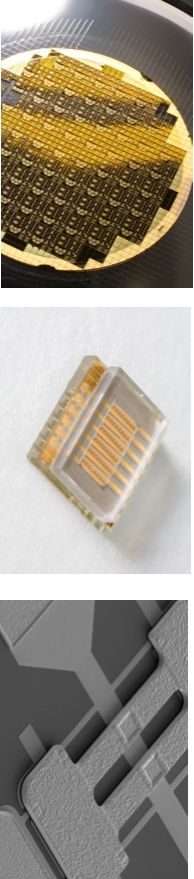

While the DMS Power Relay retains the galvanic isolation properties of traditional mechanical relays, Menlo says the ability to integrate it into traditional semiconductor packages (like System-in-Package or Multi-Chip-Modules) makes it possible to provide other intelligent features. DMS technology is manufactured using a wafer-level manufacturing process, so the chips can benefit from the scale and cost structure typical for semiconductor products, Menlo says.

Awesome! Its actually aweeome paragraph, I have

got much clear idea about from this piece of writing.