New standards for combined 48-V/12-V vehicles dictate stringent tests for overvoltages and currents that new converter ICs can help meet.

Tony Armstrong | Analog Devices Inc.

The 48/12-V automotive battery system is just around the corner. Most major automobile manufacturers have been perfecting such systems for past few years, and it is evident that their first implementations will be relatively near term.

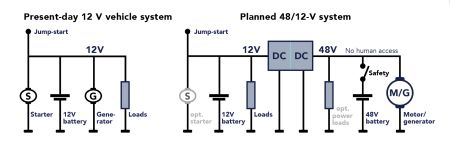

The typical 48/12-V system consists of two separate branches of power. The traditional 12-V bus uses a conventional sealed lead-acid (SLA) battery to handle traditional systems such as infotainment, lighting, and windows. The new 48-V system will support heavier loads such as the starter/generator, A/C compressors, electric turbochargers, and regenerative braking. Vehicle electrical components will either run off the 48-V Li-ion battery or the 12-V SLA – but not both.

The point of the 48-V system is to reduce weight in the wiring harness. The higher voltage allows use of less current for the same amount of power and thus makes it possible to employ lighter, lower-gauge wiring. The advantage becomes clear from the fact that high-end vehicles today can carry more than 4 km of wire.

The move to 48/12-V systems is a necessary and crucial step in the long and arduous journey to the fully autonomous passenger vehicle. The transition doesn’t mean the 12-V battery is going away; there are far too many legacy 12-V systems in the installed vehicle base for this to happen anytime soon.

Nevertheless, use of 48/12-V systems introduce complexities. There must be two separate charging circuits for these individual batteries because of their respective chemistries. Additionally, there must be a mechanism to safely move charge between them.

While dual batteries certainly complicate the design of the various vehicle electrical sub-systems, there are advantages to be gained. For one thing, having two batteries allows for redundancy should one fail. And according to some auto makers, a 48-V electrical system results in a 10-15% gain in fuel economy for internal combustion engine (ICE) vehicles, thus reducing CO2 emissions. Moreover, future vehicles that use a dual 48/12-V system will enable the integration of electrical booster technology that operates independently of the engine load, thereby improving acceleration. Such compressors are already in the advanced stages of development and will reside between the induction system and the intercooler, using the 48-V rail to spin-up their turbos.

Meanwhile, the proliferation of new electrical systems and connectivity within vehicles has brought the 12-V electrical system to its usable power limit. These changes, coupled with increased demands for power, have created the need for supplementing the 12-V SLA battery system with its 3-kW max output.

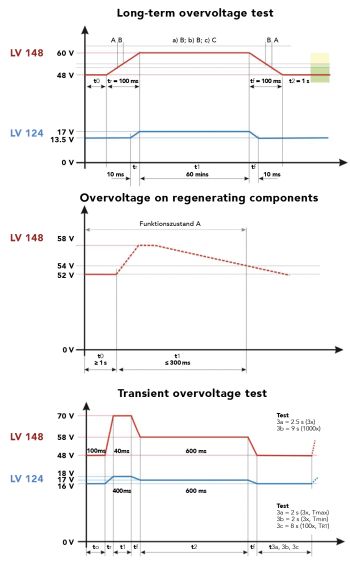

New automotive standards spell out some facets of how 48/12-V systems must function. A newly proposed automotive standard, known as LV148, calls for a secondary 48-V bus that works with the existing 12-V system. In 2011, this standard was adopted by the Big Five German automakers – Audi, BMW, Daimler, Porsche, and Volkswagen – and spells out electrical requirements and test procedures for 48-V components. According to LV148, the 48-V rail is to include an integrated starter generator (ISG) or belt start generator, a 48-V lithium-ion battery, and a bidirectional dc/dc converter able to deliver 10 sec of kilowatt-level energy from the 48-V and 12-V batteries combined. This technology is aimed at conventional ICE automobiles, as well as hybrid electric and mild hybrid vehicles.

Integrating 48/12-V battery systems

LV148 requires that the 12-V bus continuously power the ignition, lighting, infotainment and audio systems. It uses the 48-V bus to power bigger loads — active chassis systems, A/C compressors, and so forth, and to participate in regenerative braking.

In this regard, Analog Devices’ Power by Linear (PbL) group designed and developed dc/dc converters able to transfer higher levels of energy with high efficiency, thus conserving energy while simultaneously minimizing thermal design aspects.

Specifically, 48/12-V systems call for a bidirectional step-down and step-up dc/dc converter that spans the two voltages. The converter plays a role in charging either of the batteries while simultaneously allowing both batteries to supply current to the same load if that’s what is required.

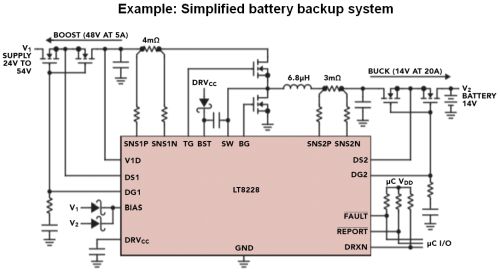

The first 48/12-V dual battery dc/dc converters to come off the drawing boards used different power components to step-up and step-down the voltage. However, ADI’s recently introduced LT8228 bidirectional dc/dc controller uses the same external power components for the step-up conversion as for step-down conversion. This part is a 100-V bidirectional constant-current or constant-voltage synchronous buck or boost controller with independent compensation networks.

The LT8228 automatically determines the direction of power flow or the direction can be externally controlled. Input and output-protection MOSFETs protect against negative voltages, control inrush currents, and provide isolation between terminals under fault conditions such as shorts in the switching MOSFETs. In step-down mode, protection MOSFETs prevent reverse current. In step-up mode, the same MOSFETs regulate the output inrush current and use an adjustable timer circuit breaker to protect themselves.

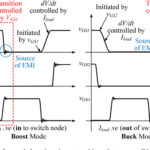

The LT8228 controller provides a step-down output voltage when in buck mode or a step-up output voltage when in boost mode. The input and output voltage can be set as high as 100 V. In applications such as battery backup systems, the bidirectional feature allows the battery to be charged from either a higher or lower voltage supply. When the supply is unavailable, the battery boosts or bucks power back to the supply.

To optimize transient response, the LT8228 has two error amplifiers, one for boost mode, the other for buck mode with separate compensation pins. The controller operates in discontinuous conduction mode when reverse inductor current is detected for light load conditions.

The LT8228 brings a new level of performance, control and simplification to 48/12-V dual battery dc/dc automotive systems. During starting or when the vehicle needs additional power, the LT8228 allows both batteries to supply energy simultaneously to the same load. Thus this bidirectional converter helps designers easily configure the 12-V and 48-V battery systems which will be required for the fully autonomous vehicles of the near future.

Leave a Reply