Liquid cooling comes in two forms, cold-plate based systems, and immersion cooling systems. Cold plate liquid cooling is found in various high-performance applications, including energy storage, transportation, electric vehicles, photonics, LEDs, military and industrial power supply cooling, even in some over-clocked desktop computers. The use of immersion cooling is more limited, and it can be found in applications such as high-performance computing clusters (HPCC), green data centers, and cryptocurrency mining operations. Liquid immersion cooling is also used with some LEDs, lasers, X-ray machines, and magnetic resonance imaging systems.

Cold-plate liquid cooling

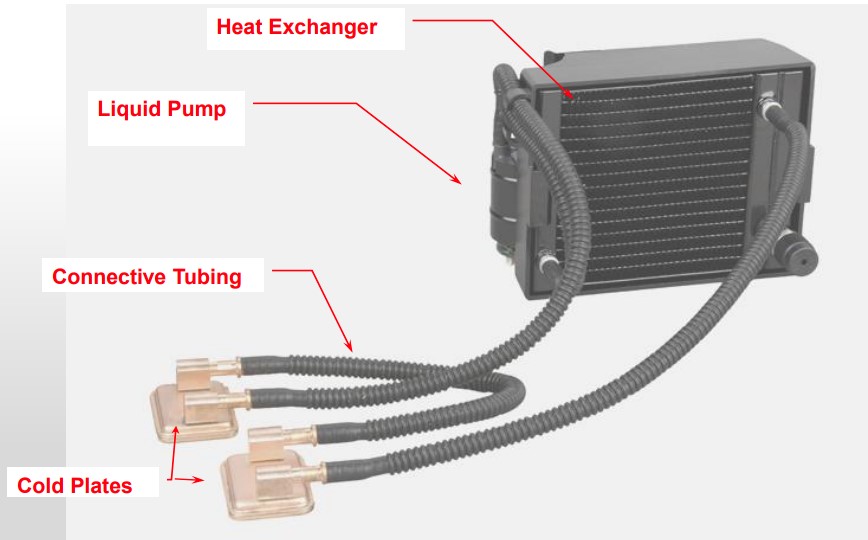

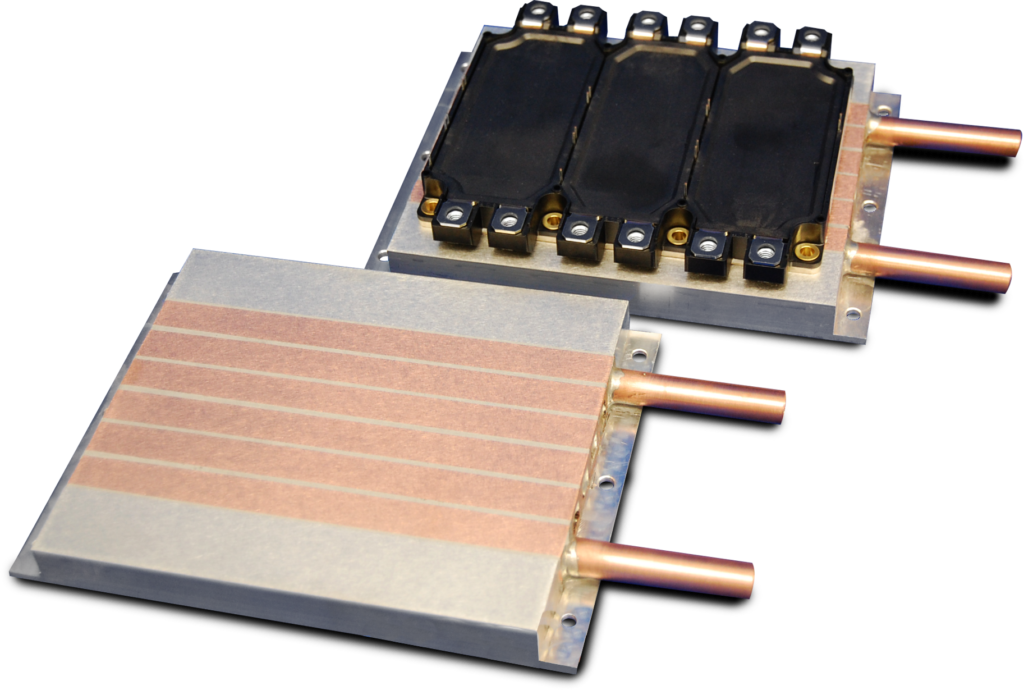

Cold-plate liquid cooling systems are up to four times more effective at transferring heat compared with forced air cooling. This allows higher performance cooling to be provided with a smaller system, and a cold-plate system can be more flexible in its mechanical design since it does not rely on system airflow. A liquid-cooled cold plate can replace space-consuming heat sinks and fans with one or more liquid cold plates, a pump, a heat exchanger, and tubing.

For liquid cold plates, the choice of working fluid is as important as choosing the hardware pieces. The wrong liquid can lead to poor heat transfer, clogging, and even system failure. A proper heat transfer fluid should provide compatibility with the system’s metals, high thermal conductivity, and specific heat, low viscosity, low freezing point, high flash point, low corrosivity, low toxicity, and thermal stability.

While water provides superior cooling performance in a cold plate, it is not always practical because of its freezing temperature and corrosive characteristics. Additives such as glycol are often needed to change a coolant’s characteristics better to suit a cold plate’s operating environment better.

Operating temperature range is usually the main consideration for a cold plate fluid. Some fluids freeze at lower temperatures than water but have lower heat transfer capability. The selected fluid must also be compatible with the cold plate’s internal metals to limit corrosion potential. The most commonly used coolants for liquid cooling applications today are:

- Water – Water has high heat capacity and thermal conductivity. It is compatible with copper, which is one of the best heat transfer materials. The use of pure water is recommended to minimize corrosion and optimize thermal performance. The use of deionized water is often preferred.

- Deionized water – The deionization process removes harmful minerals, salts, and other impurities that can cause corrosion or scale formation. Compared to tap water and most fluids, deionized water has a high resistivity. However, as water’s resistivity increases, its corrosivity increases as well. When using deionized water in cold plates or heat exchangers, stainless steel tubing is recommended.

- Inhibited glycol and water solutions – The two types of glycol commonly used for liquid cooling applications are ethylene glycol and water (EGW) and propylene glycol and water (PGW) solutions. Ethylene glycol has desirable thermal properties, including a high boiling point, low freezing point, stability over a wide range of temperatures, and high specific heat and thermal conductivity. It also has a low viscosity and, therefore, reduced pumping requirements. PGW is used in applications where toxicity is a concern. PGW is recognized as safe for use in food or food processing applications and can also be used in enclosed spaces.

- Dielectric fluids – A dielectric fluid is non-conductive and therefore preferred over water when working with sensitive electronics.

- Perfluorinated carbons are non-flammable, non-explosive, and thermally stable over a wide range of operating temperatures. Although deionized water is also non-conductive, Perfluorinated carbons are generally less corrosive than deionized water. However, it has a much lower thermal conductivity and a much higher price.

- Polyalphaolefin (PAO) is a synthetic hydrocarbon used for its dielectric properties and a wide range of operating temperatures. Like perfluorinated carbons, PAO has much lower thermal conductivity than water.

Immersion cooling for high-performance computing

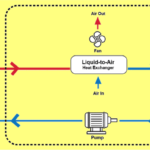

In immersion cooling, heat is removed from the system by circulating liquid into direct contact with hot components and cool heat exchangers. Fluids suitable for immersion cooling have very good insulating properties to ensure that they can safely come into contact with energized electronic components. There are two main liquid categories, Hydrocarbons (mineral, synthetic or bio-oils) and fluorocarbons. Immersion cooling systems have over a decade of successful deployments in data centers. Benefits claimed from using immersion cooling in data centers include:

- Eliminating hot spots, vibrations, and environmental contaminants

- Preventing hardware oxidation and corrosion and reducing failure rates

- Cutting server power consumption up to 30%

- Decreasing core chip temperature by 20°C

- Lowering the operating temperatures of all components

- Increasing rack density and optimizing floor space

- Reducing maintenance time and costs for cooling system and IT equipment

Dielectric liquids for immersion cooling are divided into single- and two-phase applications.

- Single-phase uses a circulation method for the dielectric liquid across hot electronic components and a heat exchanging approach.

- Two-phase immersion uses a low-temperature evaporation process to cool hot electronics and transfer the liquid’s heat. The gas is cooled again by a heat exchanging method to allow return flow into the larger liquid volume.

Cool shapes and forms

“Enclosed chassis” immersion cooling designs require dripless connectors to interface to the individual chassis. These chassis are usually based on traditional rack style implementations. The dripless connectors usually require a small closed-circuit cooling loop with a coolant to protect the flow integrity through relatively small pipes and connectors. The closed-circuit is facilitated by a coolant distribution unit (CDU), which usually can facilitate multiple racks at once.

“Open bath” refers to the “open” liquid-air interface. Open bath systems are usually tanks that contain a larger body of dielectric liquid where electronics are immersed in the bath. Multiple electronic assemblies share the same liquid. This liquid can be based on single- or two-phase technology. Regardless of the term, open bath systems can be fully sealed but are always opened from the top to service IT equipment. The liquid circuit for open bath immersion systems is connected to a CDU that circulates the dielectric liquid or to an integrated heat exchanging device, which is part of the tank. CDU’s are usually designed for 100kW or more for facility-scale cooling, while an integrated heat exchanging device is usually designed for 10-100 kW of cooling capacity.

“Hybrid” refers to combinations of the enclosed chassis and open bath forms. There are numerous solutions in the industry already with unique and diverse approaches. These may not always fit in any designated definition. Depending on which aspect is dominant, these strategies may be positioned as any overlapping definition.

This thermal management FAQ series has looked at; “Basic principles of thermal management,” “Convection cooling components,” “Forced air cooling keeps cool with fans and blowers,” and concluded with this discussion of “Liquid cooling for high-performance thermal management.”

References:

Choosing the Right Fluid to Use with Cold Plates, Advanced Thermal Solutions

How to Design a Liquid Cooled System, Semi-therm

Immersion cooling, Wikipedia

Optimize Any OEM Server for Immersion Cooling, Green Revolution Cooling

Leave a Reply