Researchers at the University of Buffalo have come up with a MOSFET made from the unusual material gallium oxide. The point of the work is that gallium oxide has a bandgap of about 4.8 eV, better than that of SiC’s 3.4 eV or GaN at 3.3 eV or silicon at 1.1 eV. Bandgap measures the amount of energy needed to boost an electron into a conducting state. Systems made with the high-bandgap material can be thinner, lighter and handle more power than those from materials with lower bandgaps. Also, a high bandgap enables operation at higher temperatures, reducing the need for cooling.

Specifically, researchers say they used a combination of atomic-layer-deposited and plasma-enhanced chemical-vapor-deposited SiO2 layers to enhance the breakdown voltage of a spin-on-glass source/drain doped lateral Ga2O3 MOSFET. The three-terminal breakdown voltage reached 1,850 V for a Lgd=20 μm device. They say this is the first report of a lateral Ga2O3 MOSFET exhibiting more than a 1.8 kV breakdown voltage.

Specifically, researchers say they used a combination of atomic-layer-deposited and plasma-enhanced chemical-vapor-deposited SiO2 layers to enhance the breakdown voltage of a spin-on-glass source/drain doped lateral Ga2O3 MOSFET. The three-terminal breakdown voltage reached 1,850 V for a Lgd=20 μm device. They say this is the first report of a lateral Ga2O3 MOSFET exhibiting more than a 1.8 kV breakdown voltage.

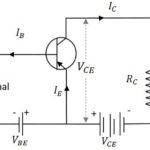

The study’s lead author Uttam Singisetti, Ph.D., associate professor of electrical engineering in UB’s School of Engineering and Applied Sciences, and his students (Ke Zeng and Abhishek Vaidya) fabricated a metal-oxide-semiconductor-field-effect transistor (MOSFET) made of gallium oxide that’s five micrometers wide. A sheet of paper is about 100 micrometers wide.

Breakdown voltage is the amount of electricity required to transform a material (in this case, gallium oxide) from an insulator to a conductor. The higher the breakdown voltage, the more power the device can handle.

As transistors go, the Ga2O3 device is relatively large. Singisetti thinks it could be useful for inverters as found in solar and wind installations, as well as in electric vehicles including cars, trains and aircraft.

“Gallium oxide may allow us to reach, and eventually exceed, silicon-based devices while using fewer materials. That could lead to lighter and more fuel-efficient electric vehicles,” Singisetti says.

A description of the work appears in the Sept. issue of IEEE Electron Device Letters ( Volume: 39, Issue: 9): https://ieeexplore.ieee.org/document/8418393/?part=1

Interesting work. Wonder if this might be suitable for some applications where current (eg SiC/etc) transistors simply are not good enough?