SMP Sintermetalle Prometheus GmbH & Co KG (SMP) introduces inductive components for environmental applications. The components are fitted in inverters, power converters, and high-frequency converters, which are installed for example in waste and raw material recycling plants, in garbage processing, or in sewage and water treatment plants. The chokes, EMC filters, mid-frequency transformers, and soft magnetic cores from SMP are extremely energy-efficient, low-loss, and designed to perform flawlessly even in harsh environmental conditions.

SMP Sintermetalle Prometheus GmbH & Co KG (SMP) introduces inductive components for environmental applications. The components are fitted in inverters, power converters, and high-frequency converters, which are installed for example in waste and raw material recycling plants, in garbage processing, or in sewage and water treatment plants. The chokes, EMC filters, mid-frequency transformers, and soft magnetic cores from SMP are extremely energy-efficient, low-loss, and designed to perform flawlessly even in harsh environmental conditions.

Components in environmental applications must withstand challenging environmental conditions such as dirt, dust or moisture, extreme weather, and high temperatures. In order to satisfy these requirements, the components conform to thermal class H (180°C) according to DIN EN 60085, fire protection class HL3 according to DIN EN 45545, and protection class from IP00 to IP66 according to DIN EN 60529. Thus, components from SMP can be used in PD4 environmental conditions, both inside and outside the power converter or electric plant. Cooling methods for which the components are suitable include air cooling, water cooling, and free convection. To guarantee long-term operation, reliability is also a key factor in environmental applications. Consequently, many components from SMP have been in operation for more than 30 years without breakdown.

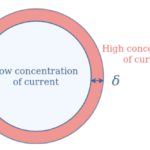

In order to ensure the long-term conservation of resources and minimize ongoing operating costs, the components must maintain an optimal energy balance. The materials for the components are developed and produced by SMP, especially for this purpose, and are characterized by minimal eddy current and hysteresis losses. The materials are exceptionally energy-efficient, enabling the manufacture of extremely low loss, compact components with high energy density and maximum efficiency, however demanding the requirements. In order to minimize their impact on the environment, humans, and wildlife, all powder-metallurgical materials are magnetostriction-free, which means that they are completely noiseless. The closed construction of the components minimizes the magnetic stray field, which is not only beneficial for adjacent electronic components, it also prevents interference with the keen senses of animals in the vicinity of the plants. The compact construction with the smallest possible volume and weight also offers savings with regard to the installation space required.

The range of uses for the components from SMP extends from currents up to 3000 A, frequencies up to 5 GHz, and a saturation flux density of up to 2 Tesla. All components are RoHS- and REACH-compliant and CE, EAC, and UKCA certified. The materials used are UL listed.

Leave a Reply