Researchers at the Massachusetts Institute of Technology say they’ve developed a “smart power outlet” that can distinguish between benign electrical spikes from common household appliances and dangerous arcs that could lead to a fire. They say their device can also be trained to discern the appliance plugged into a particular outlet, such as a fan versus a desktop computer.

The team used a Raspberry Pi Model 3 board and an inductive current clamp on the ac line. The signal from the current clamp went to an ordinary USB sound card which hosts a built-in 48-kHz A/D converter and an integrated memory buffer, enabling the real-time monitoring of electrical activity.

The Raspberry Pi runs a neural network program trained to establish “definitions,” or recognize associated electrical patterns, produced by four device configurations: a fan, an iMac computer, a stove-top burner, and an ozone generator — an air purifier known for producing arcs when producing ozone by electrically charging oxygen in the air. The machine learning algorithm running on the Pi determines whether a signal is harmful or not by comparing it to others previously used to train the system.

After training the network, researchers ran their setup on new data from the same four devices and could discern between the four types of devices (for example, a fan versus a computer) with 95.61% accuracy. In identifying good from bad signals, the system achieved 99.95% accuracy — slightly higher than existing AFCIs. The system was also able to react quickly and trip a circuit in under 250 msec, matching the performance of contemporary, certified arc detectors.

Joshua Siegel, a research scientist in MIT’s Department of Mechanical Engineering, foresees a wider deployment of smart power outlets use that beam their findings to the cloud. These data, such as the kind of appliances plugged in, and the time and reason for an outlet tripping, would be securely and anonymously shared with the team to further refine their machine-learning algorithm, making it easier to identify a machine and to distinguish a dangerous event from a benign one.

“By making IoT capable of learning, you’re able to constantly update the system, so that your vacuum cleaner may trigger the circuit breaker once or twice the first week, but it’ll get smarter over time,” Siegel says. “By the time that you have 1,000 or 10,000 users contributing to the model, very few people will experience these nuisance trips because there’s so much data aggregated from so many different houses.”

Siegel and his colleagues have published their results in the journal Engineering Applications of Artificial Intelligence. His co-authors are Shane Pratt, Yongbin Sun, and Sanjay Sarma, the Fred Fort Flowers and Daniel Fort Flowers Professor of Mechanical Engineering and vice president of open learning at MIT.

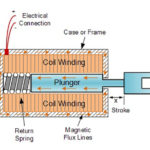

AFCI designs often evaluate the current waveform of the load in an attempt to identify qualities that typify the waveforms generated by arcing faults. One key quality of arc faults is the presence of high-frequency energy when current flows through an arcing junction. A significant amount of arc energy spreads throughout a wide-band frequency spectrum in a pink-noise pattern that spreads throughout the complete frequency spectrum. AFCI designs take into consideration high-frequency content to validate the presence of arcing faults in the line and any source of noise coupled to the line that can potentially affect their performance.

The problem is that some products, such as personal computers, can exhibit some of the same qualities as dangerous arcs. UL imposes a lengthy test procedure to ensure that the AFCI can differentiate between these signals and not be masked from responding to the similar (but different) arcing waveform.

Additionally, some electrical products, once turned on, draw a high current. This start-up inrush current level will be several times the normal operating current and decays to the steady state current over several cycles. Certain electronically controlled products may use starting techniques in which the rate of rise in the current (di/dt) may be quite high, while the trailing edge may assume the partial shape of the ideal sinusoidal waveform. This waveform is typical of thyristor starting controls and can be interpreted as an arcing fault under some conditions

Leave a Reply