Regulatory standards cover safety and electromagnetic compatibility (EMC) and efficiency. Safety and EMC standards are relatively straightforward, and their numbers are limited. Efficiency is a different matter: Society’s drive to reduce greenhouse gas emissions results in increasingly sophisticated energy efficiency standards for all types of power converters. It started with relatively simple ENERGY STAR standards for external power supplies in the 1990s. Today, there are standards tailored for the specific operating conditions of various applications, ranging from data center power supplies to white goods, LED light bulbs, electric vehicle battery chargers, photovoltaic inverters, and others. And the standards cover much more than efficiency. There are detailed standards for EMI, surge protection, and many other performance parameters. There are three primary categories of regulatory standards that designers need to focus on:

- Safety standards

- Electromagnetic interference/electromagnetic compatibility (EMI/EMC) standards

- Efficiency standards

These requirements can be mandatory or voluntary, depending on the application and region where the device is used (Figure 1). These standards have varying levels of required documentation and enforcement. The primary international sources for these standards are the International Electrotechnical Commission (IEC) and the related International Organization for Standardization (ISO). These international standards usually serve as the source of the requirements in national and regional standards from bodies such as Underwriters Laboratories (UL), Canadian Standards Association (CSA), Verband der Elektrotechnik (VDE), Technischer Überwachungs-Verein (TUV), European Norms (EN), British Standards Institution (BSI), the Federal Communications Commission (FCC), and others.

Figure 1: Power supply safety standards and marks. (Image: CUI)

Figure 1: Power supply safety standards and marks. (Image: CUI)

Safety standards

The IEC is the original source for many safety standards for electronic devices. In addition to local versions, IEC standards usually have multiple iterations or editions. There’s a large and growing number of safety standards. The following is a summary of a few of the more important ones:

IEC 60601 applies to the safety and essential performance of medical electrical equipment. In addition to the basic standard, it includes about ten collateral standards and nearly 80 application-specific standards. Some of the national standards based on 609601 deviate from the basic requirements.

IEC 61010 standard addresses the safety of laboratory, inspection, and measurement equipment. This includes electrical equipment for measurement and control in laboratory use. Types of laboratory equipment covered by the IEC 61010 family of standards include: Test and measure equipment – Tests measure, indicate, or record electrical or non-electrical quantities; Laboratory equipment – Measures, indicates, monitors, analyzes, or prepares materials; Benchtop power supplies within test and measurement equipment; and Computing equipment – Part of the equipment standard or designed exclusively for the equipment.

IEC 80601-2-60:2019 applies to dental units’ basic safety and essential performance, dental patient chairs, dental equipment, and dental operating lights.

IEC 62368-1, the hazard-based product-safety standard for ICT and AV equipment, replaced IEC 60950-1 for ICT equipment and IEC 60065 for AV equipment. IEC 62368-1 uses fundamentally different engineering principles and terminologies compared with the two standards it replaced, and some products that complied with 60950-1 or 60065 will need to be recertified to 62368-1. In addition, while the earlier standard applied only to end-user products, the new standard applies to components and subsystems such as power supplies.

IEC 60335-1 safety standard for household electrical appliances applies to devices with rated voltages of up to 250 Vac single-phase or 480 Vac multi-phase. The emergence of smart appliances merging with the Internet of Things (IoT) has resulted in complex appliances with various new functions, including displays, wireless communications, and software that can impact the product’s safety. In addition to the general requirements of part 1, part 2 includes additional requirements for over 100 device types. IEC 60335-1 includes two categories of leakage current limitation; portable appliances and stationary appliances. Portable appliances are limited to 0.75 mA, while stationary and movable devices are limited to 3.5 mA. Creepage and clearance distances are also important considerations.

Creepage and clearance

Clearance is the distance between two conductive parts through the air, while creepage is the shortest distance between two conductors along a surface (Figure 2). Clearance prevents ionization of the airgap. The length of the needed airgap to prevent a flashover is related to relative humidity, temperature, and pollution degree. Because clearance distance is intended to avoid a flashover, the maximum peak voltage, including expected transients, is used to determine clearance spacing. IEC 60950-1 specifies 4.0 mm of clearance with reinforced insulation and a working voltage between 250 and 300 volts, while the IEC 60335-1 requirement is 3.5 mm.

Creepage distance is intended to prevent the development of a conductive path along the surface of an isolator due to a high voltage applied over time. It’s related to the RMS value and depends on environmental conditions, described by the isolator’s material characteristics and the pollution degree. IEC 60335-1 requires 8.0 mm of creepage for reinforced insulation when the working voltage is between 250 and 300 volts, while IEC 60950-1 specifies only 6.4 mm creepage. When the working voltage is between 200 and 250 V, both standards call for 5 mm of creepage.

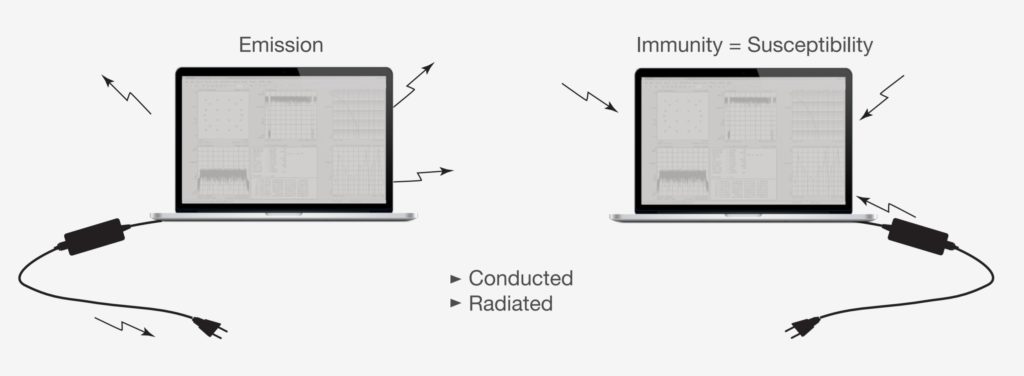

EMI/EMC standards

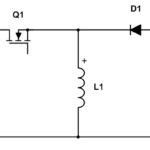

EMI relates to the transmission or emission of potentially harmful electromagnetic radiation by a device or system, and EMC relates to the susceptibility of a system to the EMI emitted from other systems or sources. EMI/EMC can take the form of conducted and radiated energy (Figure 3). Conducted emissions refer to EM energy generated by a system or device and transmitted through its power cord to other devices. Radiated emissions refer to EM energy radiated through free space and received by other devices. As a result, there are four EMI/EMC concerns:

- Conducted emissions

- Radiated emissions

- Conducted susceptibility

- Radiated susceptibility

EMI/EMC requirements are much more limited in number and are more locally promulgated. The two basic standard-setting regions are the US and the EU. The Federal Communications Commission (FCC) is the US body, and in the EU, EMI/EMC is covered by the Electromagnetic Compatibility (EMC) Directive 2014/30/EU. CISPR (Comité International Spécial des Perturbations Radioélectriques) is also still cited, although most CISPR standards have equivalent EN standards (Table 1). Most other countries have harmonized standards to either the FCC or EU EMC Directive. In addition, informal military standards for EMC have existed since the 1940s, with the first version of MIL-STD 461 published in 1967. While MIL-STD-461 compliance is technically not required outside the US military, many civilians and military organizations use this document.

Some common EMI and EMC standards include:

CISPR 22: Information Technology Equipment – Radio Disturbance Characteristic limits; corresponds to European standard EN 55022. This is the standard that is often referenced in all European EMC standards, defining measurement methods, measurement equipment, limit lines, and interpretation of the applicability of limit lines, starting from household appliances to medical devices.

CISPR 24: Information technology equipment – Immunity characteristic limit; closely related to EN 55024.

EN 55022: European limits of radio disturbance characteristics for IT equipment

EN 55024: European immunity requirements for IT equipment

FCC Part 15: US regulations for radio-frequency emissions and immunity

IEC 61000 series of EMI and EMC specifications. For example, IEC 61000-3-2 Electromagnetic compatibility (EMC) – Part 3-2: Sets limits for harmonic current emissions (equipment input current ≤ 16 A per phase) by prescribing the maximum value for harmonic currents from the second harmonic up to and including the 40th harmonic current. IEC 61000-3-2 applies to equipment with a rated current up to 16A. The corresponding EU standard is EN 61000-3-2. IEC 61000-3-12 applies to equipment above 16A.

These are system-level standards. While some subsystems such as power supplies claim to meet specific EMI/EMC standards, the complete system must meet the requirements.

Efficiency standards

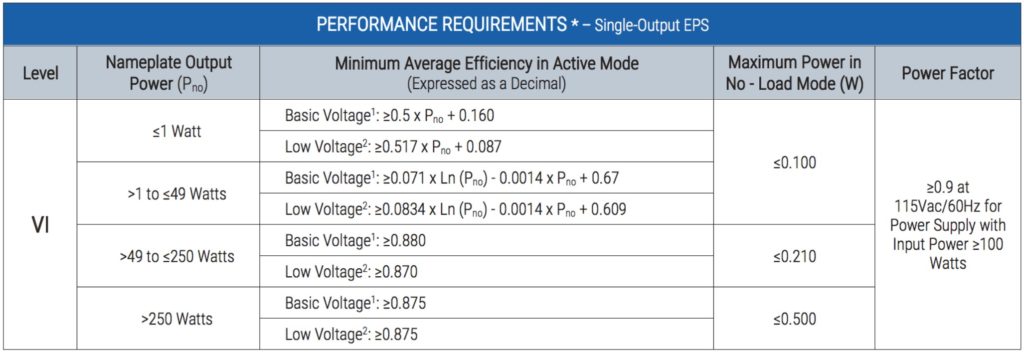

Efficiency standards are set by national governments and more locally, such as the California Energy Commission (CEC). In fact, the CEC set the first mandatory efficiency standards for external power supplies in 2004. Until then, there were only guidelines from ENERGY STAR and other agencies. More recently, the Department of Energy (DOE) was instrumental in developing the International Efficiency Marking Protocol (IEMP). The IEMP specifies Roman numeral markings for external power supplies, indicating their efficiency level. Many countries and regions have now implemented mandatory and voluntary standards for external adapters.

The US is currently at DoE Level VI, which is a mandatory regulation (Tables 1 & 2), and Canada has harmonized with the US’s Level VI performance requirements. The EU uses Commission Regulation (EU) 2019/1782 or Ecodesign 2019/1782 is generally harmonized with Level VI but requires additional documentation and reporting. The EU Code of Conduct (CoC) Tier 2, if it becomes adopted, is even more restrictive on power supply efficiency.

Power conversion efficiency is also important (but less regulated) for internal or embedded supplies to meet voluntary standards at the system level, such as ENERGY STAR. To earn the ENERGY STAR, products must meet specified energy efficiency criteria set by the US Environmental Protection Agency or the US DoE. Examples include:

- Qualified refrigerators are at least 15% more efficient than the minimum federal efficiency standard.

- Qualified TVs consume 3 watts or less when switched off than a standard TV, consuming almost 6 watts on average.

- Office equipment that qualifies automatically enters a low-power “sleep” mode after a period of inactivity.

- Qualified light bulbs (CFLs) use two-thirds less energy than a standard incandescent bulb and must meet additional operating and reliability guidelines.

Summary

The landscape of safety, EMC and efficiency standards is complex and subject to change. Some standards disappear or are combined with other standards at the same time that new standards are emerging. The primary goal of all standards is protection: Protection of users from physical harm. Protection of adjacent devices from interference with their operation. And protection of the environment through the minimization of greenhouse gas emissions. Depending on the device and application, designers must be aware of and contend with regional, national, and even local performance standards.

References

Electrical safety and isolation in high voltage discrete component applications and design hints, Infineon Technologies

Making Conducted and Radiated Emissions Measurements, Keysight Technologies

Power Supply Safety Standards, Agencies, and Marks, CUI

What is Level VI?, SL power

Safety Power Supplies