Peltier modules, also known as thermoelectric coolers (TEC) or thermoelectric modules (TEM), are solid state devices which transfer heat when electrical power is applied. As with many components, the reliability of Peltier modules is of great importance in applications, so it is beneficial to have some basic knowledge regarding their construction and proper implementation.

Peltier modules, also known as thermoelectric coolers (TEC) or thermoelectric modules (TEM), are solid state devices which transfer heat when electrical power is applied. As with many components, the reliability of Peltier modules is of great importance in applications, so it is beneficial to have some basic knowledge regarding their construction and proper implementation.

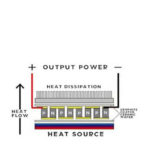

It can be difficult to quantify the reliability of Peltier modules due to the large dependence upon operating conditions. However, many factors have been discussed which contribute to degradation of their reliability. Some of the factors are related to the mechanical installation of the modules (shear and torque stresses), while other factors are related to the operating conditions (temperature, temperature gradient, and temperature slew rate). Chemical contamination can also be an issue in some applications. Improved Peltier module assembly technologies help to mitigate mechanical failure mechanisms and thus contribute to improved reliability.

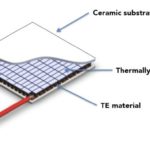

The construction of Peltier modules has been addressed in this CUI Devices whitepaper, but CUI Devices’ Bruce Rose provides a quick refresher of Peltier module construction followed by a summary of common failure mechanisms and ways to improve TEC reliability in his latest CUI Insights blog.

Leave a Reply