by Jeff Davis, Engineering Manager, Energy Efficient Lighting, Intertek, Arlington Hts., Ill.

What you need to know about today’s energy efficiency lighting standards, the benefits of compliance, and the role of third-party testing labs.

The Energy Policy and Conservation Act of 1975 and its subsequent amendments established minimum efficiency standards for lighting products. This was the impetus for a host of programs and benchmarks for energy efficiency standards.

Overall, the growth and increasing variety of energy-efficient lighting products over the past several decades has led to the development of numerous voluntary certification programs and initiatives designed to measure and reflect their performance and efficiency. Today, compliance with any or all of these voluntary programs can be a significant source of differentiation, revenue, leadership, promotion, and pride for lighting manufacturers—factors which represent compelling reasons for manufacturers to invest time and resources into the pursuit of achieving these voluntary standards.

U.S. and Canadian markets have seen an increase in “green” lighting certification programs and initiatives over the years. The opportunity to differentiate one’s product has led manufacturers to invest time and resources into the pursuit and achievement of these voluntary program performance measures.

While voluntary programs have different objectives and requirements, all involve precise measurement and unique submission requirements to assure compliance by a skilled and accredited third-party tester.

Here we take a look at the range of voluntary energy-efficient lighting certification programs and initiatives in the U.S. including the benefits that compliance with these initiatives can deliver to lighting manufacturers, as well as how an accredited third-party tester can help ensure compliance with these programs and initiatives.

Performance Testing for Lighting Products

While reputable manufacturers typically participate in mandatory safety testing to enable their products’ retail sale in recognized establishments, performance testing is not mandatory for installation. Instead, it addresses how a product will perform when used by consumers. Throughout the lighting industry, comprehensive performance testing typically consists of assessments in three different, universally accepted areas; distribution, color, and stress/longevity.

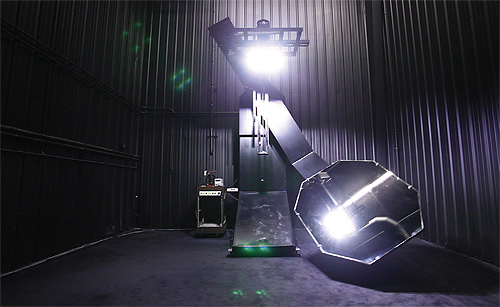

Distribution Testing – This type of performance testing measures the light pattern out of a fixture or its total light output at all different angles. For all light sources, the most accurate means of measuring a light’s distribution is through the use of a Type-C goniometer, a 30-foot-high piece of equipment used to test most residential and commercial lighting products while enabling fixtures to rotate in a horizontal plane to measure their entire light distribution. The Illuminating Engineering Society (IES) standard LM-63 specifies how the results of a distribution test should be formatted and will typically require a text file showing all lighting values at each angle.

Color Testing – This type of performance testing measures the energy of light at each wavelength and is used to calculate color temperature. The most accurate means of measuring a light’s color is through the use of an Integrating Sphere-Spectrometer system, a specially coated apparatus most commonly available in 1, 2, and 3-meter sizes which collects a light’s energy and measures it at all wavelengths. Typically, measurements with such systems include lumen or brightness level; correlated color temperature (CCT) in Kelvins ranging from 2,700 to 6,500 for consumers; color rendering index (CRI), which measures how “true” a color looks under the subject lighting; and other performance measures such as chromaticity, which is a coordinate mapping of the light’s color.

Stress and Longevity Testing – One key means of measuring a light’s lifespan is by testing it on a specially designed and controlled piece of equipment known as a Life Test Rack. These long racks can provide up to thousands of sockets that measure the longevity and durability of a broad range of lamp types in different orientations (base up, down, or horizontal) and in different ambient conditions. For LEDs, the use of IES standard LM-80 measures the individual chips that make up the lamps or fixtures; they are typically burned for 6,000 hours to determine how much their light output degrades at different levels (according to this standard, an LED would fail a stress/longevity test if its light output at 6,000 hours fell below 70% of its initial output). In contrast, a surge generator is a key piece of equipment used in the testing of stress and is typically applied to the testing of compact fluorescent and LED lamps as well as ballasts used in linear fluorescent lamps. This equipment tests to ensure that lamp samples can withstand a ringwave or combination. surge waveform without sparking or failing.

Current Programs and Performance Initiatives

Separate from the Department of Energy’s (DOE) mandated minimum energy efficiency standards, the growth of the energy-efficient lighting market has triggered the development of a number of voluntary energy-efficient lighting certification programs, performance initiatives, and labeling standards. Compliance with any or all of these can enhance a product’s eligibility for use in high-efficiency applications and upgrade projects of distinction, as well as qualify for rebate in a number of leading utility incentive programs throughout the country. Following is an overview of some of the industry’s most popular voluntary energy-efficient lighting certification programs, performance initiatives, and labeling/packaging standards for lighting products in the U.S. and Canada.

Energy-Efficient Lighting Certification Programs

ENERGY STAR – This EPA-sponsored certification program covers a variety of residential and light-commercial luminaires, lamps, light kits, and retrofit kits—particularly in the fluorescent and LED arena (previous standards in the halogen and HID technologies are currently being reviewed)—and aims to distinguish higher-efficiency products from standard or lower-performing ones. ENERGY STAR certification requires minimum performance standards in the three critical areas of distribution, color, and longevity/stress and all test data must be submitted through an EPA-recognized certification body.<

Energy-Efficient Lighting Performance Initiatives

DesignLights Consortium (DLC)—This voluntary initiative applies only to LED technology and typically covers the products not commonly comprehended by ENERGY STAR, such as high bays, wallpacks, cobra and pulse-style lighting for roadway fixtures, decorative LEDs, and LED panels for use in heavier commercial, industrial, or outdoor applications such as warehouses, manufacturing, and roadways. In addition, DLC is a utility-based initiative in that it currently feeds some 40 utilities nationwide that base rebate programs around DLC standards.

Like ENERGY STAR, DLC certification requires minimum performance standards in the three critical areas of distribution, color, and longevity/stress, but, unlike ENERGY STAR, manufacturers must take responsibility for having their products tested by an accredited body and then must submit testing reports directly to the DLC.

California Energy Commission (CEC) —Established in 1974, the California Energy Commission is responsible for planning California’s energy policy and promoting energy efficiency through the development of building and product standards. CEC standards for lamps, controls, luminaires, and other lighting products address efficiency only, not distribution, color, or longevity/stress, though their standards for ballasts and portable luminaires do serve to differentiate them from other voluntary lighting performance initiatives. CEC certification is based on the meeting of stringent product standards which can render some products eligible for utility rebates in California and other states, and which also support California-specific Title 20 and Title 24 building code standards. Like the DLC, manufacturers must take responsibility for having their products tested by an accredited body and must then submit testing reports directly to the CEC.

National Resources Canada (NRCan) —Addressing lighting product standards throughout Canada, NRCan is largely focused on performance measures related to efficiency and energy-using devices imported into Canada or shipped between provinces and must bear an energy efficiency verification mark. Minimum standards are laid out in CSA Energy Efficiency Standards and the mark must be from an SCC (Standards Council of Canada) approved certification body. Lighting products covered under NRCan include ceiling fan lighting, compact fluorescent lamps (CFLs), exit signs, fluorescent lamp ballasts, general service fluorescent and incandescent lamps, torchieres, and traffic signals and pedestrian modules. ENERGY STAR is recognized in Canada, however, and ENERGY STAR testing (if applicable) can replace NRCan testing.

Municipal Solid-State Street Lighting Consortium (MSSL)—This specialized DOE-sponsored organization offers “technical information and experiences related to LED street and area lighting demonstrations and serves as an objective resource for evaluating new products on the market intended for street and area lighting applications.” MSSL testing is largely focused on measures of distribution, color, transient, vibration, corrosion protection, and longevity.

Energy-Efficient Lighting Labeling and Packaging Standards

LED Lighting Facts Label – Neither a certification program nor a standards-setting initiative, the DOE-sponsored LED Lighting Facts Label represents a new labeling standard for all solid state fixtures and lamps (bulbs). This label is mandatory for integrated SSL lamps in the ENERGY STAR program but voluntary for other product types. The LED Lighting Facts Label provides information on lights’ brightness, appearance (warm or cool), efficacy, color accuracy, and wattage. Additional label metrics, which are optional, were added in 2012 to cover lumen maintenance and warranty. The label was designed to provide a uniform and user-friendly way for buyers and utilities to review product specifications and make comparisons between products.

One of the goals is to help change the traditional metrics from watts to one of lumens, which focuses on light output and not on power consumed.

FTC Label – The Federal Trade Commission (FTC) label is mandatory for all solid-state lighting (SSL), fluorescent, incandescent, and halogen medium screw base light bulbs only. The new FTC-sponsored Lighting Facts Label has subsequently been designed to help simplify and standardize the information shared on lighting product packaging for consumers. It includes easy-to-understand metrics such as “Estimated Yearly Energy Cost,” “Lumens,” “Lifetime,” “Light Appearance (Temperature),” and “Energy Used” to enable more apples-to-apples comparisons between products.

The Critical Role of Third-Party Testing Laboratories

Along with mandatory energy efficiency requirements established by the DOE, new voluntary energy-efficient lighting certification programs and performance initiatives run by such organizations as ENERGY STAR, DLC, CEC, NRCan, MSSL, and LED Lighting Facts involve specific standards and submission procedures which can be tedious and precise to administer, but which are critical to a company’s success.

This is where accredited third-party safety and performance testing organizations can help take the guess-work out of the process of testing and the pursuit and successful achievement of compliance.

In today’s fast-moving lighting industry, a number of issues can delay or derail a manufacturer’s efforts to achieve compliance with any or all of these programs or initiatives if undertaking their own “first-party” testing procedures. For example, the inability to structure appropriate and consistent, repeatable testing conditions could alter results, while the submission of an incorrect number of samples could make the submission invalid. In addition, technology, particularly in the LED arena, is changing quickly and manufacturers might find themselves challenged to keep up with the latest products and program requirements.

For these reasons and more, accredited third-party (external) safety and performance testing organizations can help. Their possession of and investment in the highest-tech and most precise and capital-intensive testing equipment can ensure consistent testing procedures and accurate results, while their demonstrated expertise in the unique details and current requirements of all industry certification programs and initiatives assures manufacturers of the utmost in quality coverage and representation. Along with the relationships they’ve established with all of the industry’s key certifying organizations over the years, a third-party testing lab’s exceptional understanding of and experience with the broad range of products and testing procedures can proactively support a manufacturer’s compliance while delivering security and peace of mind to both manufacturers and customers alike.

More Information on Lighting Programs and Initiatives

Further details on the Energy Star program, including links to current CFL and LED requirements for ENERGY STAR certification, are available at www.energystar.gov.

More information, including current technical requirements on DLC, can be found at www.designlights.org.

The CEC website is located at www.energy.ca.gov. Here you’ll also find information on CEC testing requirements and performance standards for lighting.

For more information on NRCan specifications, visit the linkhttp://oee.nrcan.gc.ca.

The Municipal Solid-State Street Lighting Consortium (MSSL) web site, which includes current and in-progress standards, is at www.eere.energy.gov/buildings/ssl/standards.html.

To find out more about the DOE-sponsored LED Lighting Facts and Labels standard, visit www.lightingfacts.com.

Intertek

www.intertek.com/lighting

Leave a Reply