Global technology leader Laird has developed an advanced thermoelectric module (TEM) designed for high-reliability applications like polymerase chain reaction (PCR) thermal cycling, which require extended meantime between failure (MTBF). The polymerase chain reaction (PCR) is a biochemical technology that amplifies a single copy or a few strands of DNA across several orders of magnitude, generating several hundred thousands of copies of a particular DNA sequence. PCR requires a high number of thermal cycle steps to create thousands of strands of DNA sequencing for analysis. This is a harsh environment for standard thermoelectric modules due to the mechanical stresses that occur during the heating and cooling stage.

Global technology leader Laird has developed an advanced thermoelectric module (TEM) designed for high-reliability applications like polymerase chain reaction (PCR) thermal cycling, which require extended meantime between failure (MTBF). The polymerase chain reaction (PCR) is a biochemical technology that amplifies a single copy or a few strands of DNA across several orders of magnitude, generating several hundred thousands of copies of a particular DNA sequence. PCR requires a high number of thermal cycle steps to create thousands of strands of DNA sequencing for analysis. This is a harsh environment for standard thermoelectric modules due to the mechanical stresses that occur during the heating and cooling stage.

In modern PCR devices, thermoelectric modules (TEMs) are typically used to achieve the rapid temperature changes. The advantages of thermoelectric modules over other types of thermal cycling devices are precise temperature control, compactness, faster temperature ramp rates and efficiency.

The PC Series TEMs are proven to perform for more than 800,000 temperature cycles and can operate in temperatures up to 120°C. This exceeds the requirements for PCR machines and provides a lower total cost of ownership, while increasing opportunity to sell more reagents. A copy of the validation test report can be obtained upon request.

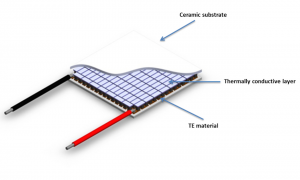

The new PC Series TEM is constructed with multiple layers between the ceramic substrates, copper buss bars and semiconductor couples. To reduce thermally induced stress, a flexible and thermally conductive “soft layer” is inserted between the cold side ceramic substrate and copper buss bars. The integration of the polymer into the thermoelectric modules absorbs the mechanically induced stresses caused by rapid temperature cycling. As a result, the stress induced on the semiconductor couples and solder joints are significantly reduced, extending the overall operational life of TEM.

“Thermal cycling exposes TEMs to mechanical stresses as the module contracts and expands from repeated cooling and heating cycles. Standard TEMs are traditionally designed for refrigeration applications only. The high-temperature diffusion of impurities and mechanical stresses over time significantly reduces the operational life of a standard TEM,” explains Senior Vice President of Laird’s Engineered Thermal Systems, Anders Kottenauer. “Our new PC Series is designed to handle hundreds of thousands of thermal cycles with minimal degradation.”

Key System Features:

- Designed to pass rigorous testing

- Robust construction developed for thermal cycling applications

- 800K+ thermal cycle operating life

- Superior temperature control stability

- RoHS Compliant

Laird

www.lairdtech.com

Leave a Reply