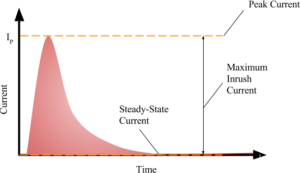

Inrush (in-rush) current is a sudden large flow of current that exceeds the usual, steady-state operating current, and can be a problem for any circuit. Inrush is most often associated with turning on equipment. Inrush current can be caused by large-capacity decoupling capacitors that draw a lot of current as they initially get charged up. Another application that invites inrush current is equipment that draws more energy until it heats up, perhaps using components that build in resistance only as the local operating temperature increases, leaving the equipment vulnerable to inrush peak currents upon initial startup.

Inrush current is short-lived; the current draw will begin to settle into a steady-state condition but this is no consolation if components get fried at startup.

Why should you care about inrush current?

In-rush current is sometimes overlooked. Inrush is often the maximum peak value of current that is actually experienced, and the tolerance of components that are in the path of inrush current should be considered. If inrush isn’t accounted for, a breaker can trip every time a piece of equipment is turned on. Adjusting the tolerance of the breaker slightly may help, as long as components can withstand the peak values at in-rush.

The duration of the peak current experienced at in-rush is also a factor. Some components can withstand brief periods of maximum current, a specification which might be found in component data sheets. Components can get very hot if there’s too large a current draw for too long, and permanent damage can occur. But you don’t have to be concerned about maximum possible inrush if you simply protect components, headers/connectors, and traces on your printed circuit board (PCB). If the current flow is choked down during initial startup, then you have little to worry about.

What can I do to protect a PCB from inrush current?

You can limit the amount of current using circuit protection devices. A passive device like a thermistor will limit current as a function of temperature. The thermistor’s resistance is at its highest when the temperature of the thermistor is at its lowest. As an example, if a power supply is turned on, it experiences a more limited amount of current if a thermistor is choking down on the maximum amount current in the inrush current path. As the thermistor operates, it heats up and resistance begins to decrease in value. This works if the thermistor is not already hot. If the capacitors discharge faster than the power supply (or thermistor) cools down, then inrush may not be adequately limited by the thermistor in every use case.

Active devices are more expensive than thermistors but work to actively switch current to bypass components at inrush. Active device options include circuits that switch incoming current away from sensitive components in what is sometimes called a “soft start,” as well as voltage regulators, DC/DC converters or low drop out (LDO) voltage regulators with built-in soft start features. Circuits that switch current away from the circuit you’re trying to protect can be discrete or integrated and may use thyristors, triode AC switches (Triacs), MOSFETs or other devices. Various integrated solutions such as load switches (e.g., Texas Instruments’ TPS229xx) can also provide the needed protection.

Factors that influence choices in circuit protection will include size, additional component cost, and power consumption. You will have to evaluate the trade-offs of a circuit protection scheme against possible use cases, product quality, reliability, and perhaps company reputation.

[…] of use, rapid application design, and fast time-to-market. This includes a proprietary internal inrush current limiting function, which saves space, reduces overall system cost, and improves reliability by […]