Leakage current flows unexpectedly in almost all circuits, even when the power is off. Current leakage is not limited to electronics, computers, or small signal circuits, and can be found in industrial equipment and three-phase wiring installations, too. Some current will always find a path to ground whether it’s through ground-conducting insulation that’s supposed to protect wiring in an electrical installation in industrial equipment wiring, or whether the current leaks through weak dielectric insulators inside capacitors that are meant as bypass or circuit protection. It’s possible for even a minute amount of current to flow through alternate pathways, circuit protection devices, and insulators of all kinds.

Leakage current becomes a problem when it affects performance or wastes energy when efficient power management is a priority. In computing, performance can be affected because computers are made up of millions to trillions of transistors that are essentially used

as electronic switches. As technology creates smaller and more efficient transistors, leakage current becomes a larger problem by comparison as insulating barriers become easier to penetrate. (Transistors may be getting smaller, but electrons are not, and so power loss through current leakage has been magnified through the progress of ever smaller nodes in semiconductor technology. Leakage current is unwanted most of the time.

Leakage current can create a constant waste of energy, and in consumer end-user circles is called “vampire power” loss; the answer to which is to unplug chargers when not in use. Power loss is not the only problem that leakage current can create, however. Current can leak from one circuit to another if the leaking current finds an easy path to ground and can be exacerbated with varying environmental conditions like temperature or with signals operating at high frequencies.

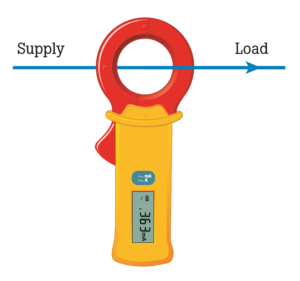

Leakage current is a fact of life. However, it can be mitigated by using better design techniques, different materials or components, and better insulators. If suspect a problem with leakage current (e.g., an appliance always shocks you or there seems to be excessive power waste with the power switch is off), you can identify the source of the leakage current through testing and measurement. If the amount of leakage current is not significant, then it’s possibly not worth your time to try and reduce leakage current. On a macro level (electrical wiring in a house, for instance) you can use an ammeter to chase down the source of flowing current while the power switch is off. An ammeter should be calibrated, clean, and used per instructions to test possible conductors, including unexpected pathways like water pipes or the grounded shielding on cables. For electronic circuits on PCBs, however, the task may require more sophisticated equipment such as an oscilloscope. In all cases, don’t forget to test unexpected conductors, including insulators that may be providing a path to ground.

Leakage Current, sometimes more precisely known as Touch Current or Protective Conductor Current depending on application and measuring technique, also can have some serious product safety consequences. A great treatment of the subject is contained in the basic safety publication, IEC 60990, “Methods of measurement of touch current and protective conductor current,” produced by Working Group 5 of IEC TC108, which is under the convenorship of Mr. Peter Perkins. I am providing a link to the preview version – https://webstore.iec.ch/preview/info_iec60990%7Bed3.0%7Db.pdf .

That’s good