By Suzana Jankuloska, Product Manager at KEMET Corporation

Capacitors developed for energy-harvesting applications bring improvements to equipment of all types and sizes, from directly powered IoT devices to grid-connected generators

Nothing new under the sun?

Ambient energy has been present in Earth’s ecosystem since the beginning of time. Humans have a long history of finding imaginative ways to harness it: baking early building materials in the sun, using the wind’s kinetic energy to grind grain and move shipping. As industrialization took hold, the demand for increased power, on demand, was satisfied using energy sources such as fossil fuels.

Now the drawbacks of fossil fuels are becoming increasingly apparent, including their finite nature, problematic emissions, increasingly difficult and costly extraction processes, and political factors that can cause supply problems and price volatility. The pendulum is swinging back towards ambient sources.

The global market for harvesting ambient energy will grow at a CAGR of 11.1% between 2019 and 2024 to reach $840 million according to MarketWatch.

Energy harvesting today

A few things have changed since ambient energy’s primitive heyday as the go-to source, including the discovery of electricity and the subsequent development of heaters and motors to handle work formerly done directly by the sun or wind. There are also efficient technologies for converting solar and wind into electrical energy, including improvements in photovoltaic cells and the commercialization of wide-bandgap power semiconductors. Economical and high-quality storage, such as various types of capacitors and batteries, is also critical, helping balance the flow of energy and ensure availability on demand.

Accompanied by a general lowering of power consumption in many types of electrical equipment, these factors together enable ambient energy to become a viable source for grid-connected generators, off-grid properties, or converters directly powering equipment such as IoT sensors and low-voltage lighting.

Grid-connected generators can range from utility-class installations such as large solar or wind farms to privately-owned micro-generators. Together, these contribute towards a distributed infrastructure that supports the move away from fossil fuels and towards renewable energy by augmenting conventional installed capacity and helping maintain the stability formerly expected from large centralized, fossil-fuel or nuclear-powered installations.

Islanded microgenerators that exclusively power local loads help reduce demands on the grid system while also cutting owners’ utility bills. Applications include not only “off-grid” homes, but also smaller loads such as roadside electronic signage and IoT equipment such as sensors and actuators that are installed remotely and connected wirelessly.

The opportunity to power equipment from ambient energy is convenient, not only saving utility costs but also saving the costs of installing power cables or sending maintenance teams to replace batteries at periodic intervals. Moreover, the equipment is also immune to any grid-power outages. Bringing the advantages of electricity to remote rural areas also becomes easier and more cost-effective.

Energy capture and conversion

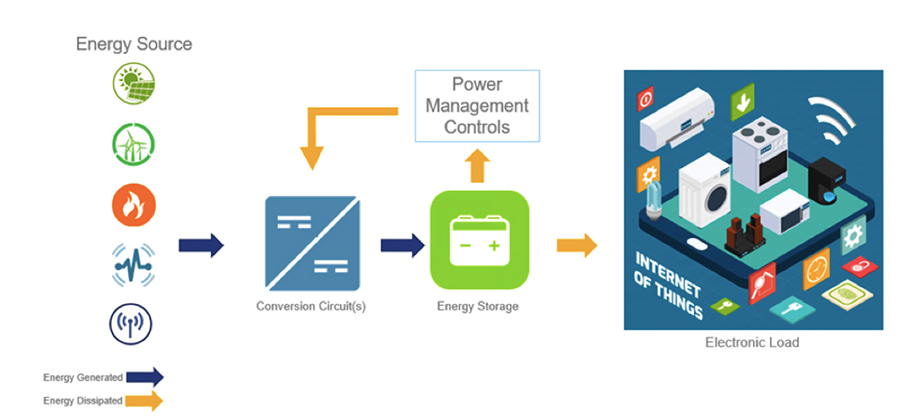

Basic components of an energy harvesting system include the energy translation device, such as photovoltaic array or wind turbine, to create electrical energy from the ambient source. The following stage comprises power conversion, storage, and management. Energy storage devices such as batteries and capacitors are critical for success, needed to help stabilize power quality and ensure availability on demand.

Ultimately, the connected load may be a small device such as a low-energy wireless module, or a larger load such as a network of smart sensors or control and monitoring devices, or low-voltage DC-distribution bus for an LED-lighting network. Figure 1 illustrates each stage generically.

In a small solar micro-generator, for example, the DC-DC converter takes in power from the photovoltaic array and outputs electricity that can be used to power devices. High energy efficiency and power quality are key system-performance indicators, to minimize wastage of the precious harvested energy and provide a stable DC supply to the load at the correct voltage and with minimal sag or ripple.

The energy storage is used to balance the energy supply and demand. To determine what energy storage is needed depends greatly on the application. A rechargeable battery, such as a Li-ion coin cell is often used in small self-powered devices that spend long periods in power-saving sleep mode and wake periodically to perform a function such as capturing a sensor reading and sending the data to an aggregating device or IoT gateway. The output of the DC/DC converter charges the battery continuously at a constant voltage, over time building up enough stored charge to power the device on a low duty cycle.

Supercapacitors in energy harvesting

As an alternative to the battery, a supercapacitor can offer advantages such as simplified charging circuitry, significantly longer cycle life, wider operating temperature range, and a high peak discharge rate for loads that require high power for a short duration. Capacitance values can be several orders of magnitude higher than conventional capacitors, in relation to volume, and the supercapacitors can be applied in conjunction with batteries to combine the best features of both device types.

Although the supercapacitor can be used in a similar way to a secondary battery, the device does not require a constant charging voltage. An energy source such as a PV-cell array is able to charge directly into a supercapacitor from 0V. if the open-circuit voltage of PV array is lower than the supercapacitor rated voltage the charging circuitry can be relatively simple, requiring little more than a blocking diode to prevent the supercapacitor discharging back into the source if light ceases to fall on the panel. A supercapacitor can discharge extremely quickly and hence deliver high peak power to the load. The device can be sized to meet the peak power demand of the load, allowing for losses due to its equivalent series resistance (ESR).

Supercapacitors are polarized devices and are available various voltage ratings. KEMET’s FS series covers ratings from 5.5V DC to 12V DC for backup and motor-drive applications. The 2.7V HV series contains nominal capacitances from 1 Farad in 12mm x 8mm-diameter radial package to 200 Farad in 50mm x 35mm-diameter. HV series devices can supply peak current up to several Amps for powering equipment such as street signage and display lighting.

Electrolytic capacitors

For applications where energy is used as soon as it is collected, storage is not always necessary. Usually, an electrolytic capacitor can be used here.

KEMET’s technology roadmap ensures aluminum electrolytic solutions to meet the evolving needs of the Energy Harvesting sector. KEMET’s High CV Screw Terminal and Snap-In series are available in 85°C and 105°C. These devices offer several attributes that make them a great fit for energy-harvesting applications, including high ripple-current capability and surge voltage capability up to 15% above the rated voltage. For the 85°C families, voltages are rated up to 630V with surge voltage of 690V. In addition, the 77mm-diameter Screw Terminal devices have the option of offset terminals to help prevent connecting the capacitor with incorrect polarity, as figure 2 illustrates.

Calculating capacitor lifetime

When choosing electrolytic capacitors for energy-harvesting applications, the lifetime of the device is a key parameter to consider. Equipment is often installed in remote locations and expected to operate for long periods with zero maintenance. Remotely installed devices may also be exposed to extremes of temperature. High temperatures, in particular, tend to shorten the lifetime of electrolytic capacitors.

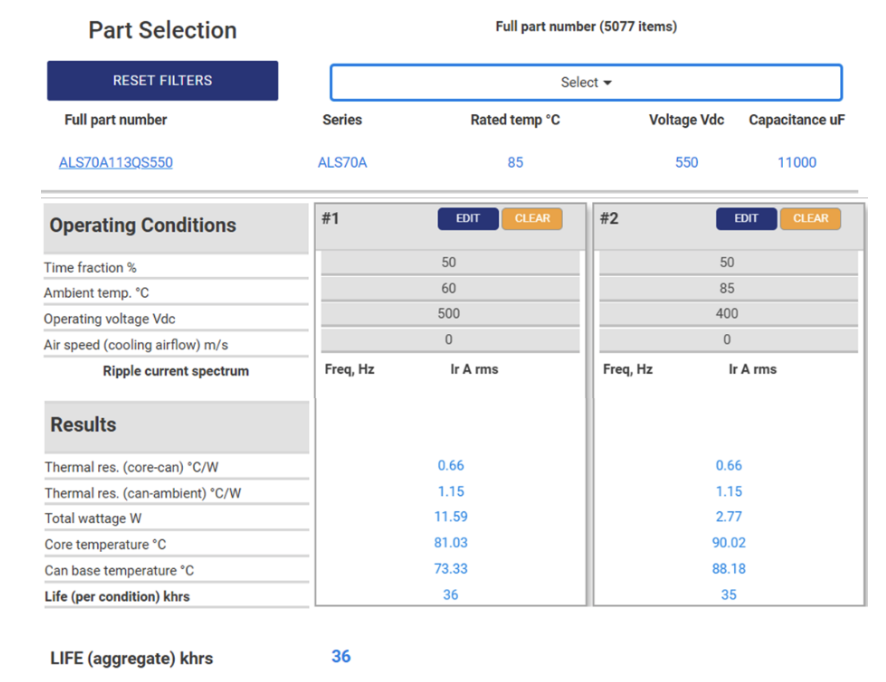

Using the life calculator at https://elc.kemet.com/ under the application operating conditions, the theoretical life expectancy can be assessed. By entering basic application details such as the duty cycle, ambient temperature and provisions for cooling, operating voltage, and ripple currents, as shown in figure 3, the lifetime can be automatically calculated based on entered end-of-life criteria such as capacitance loss, change in ESR, or change in leakage current. One advantage of KEMET’s ALS Screw Terminal electrolytic capacitors is that voltage derating is not required to ensure a long operating lifetime.

Conclusion

Harvesting ambient energy is a viable solution for applications from low-power or remotely installed electronic devices, to low-voltage infrastructures, micro-generators, and grid-connected generators. Many aspects of the components used in energy-harvesting systems have been improved to address the specific requirements of the application, including robust and efficient supercapacitors for high-speed energy delivery and long-lifetime electrolytic capacitors used to stabilize DC power delivery.

About the author

Suzana Jankuloska is a Product Manager for Electrolytic Capacitors in the Americas. She has been with KEMET since 2012. She is an enthusiast of market and technology trends specifically those requiring high voltage electrolytic capacitors. Working closely with the KEMET Innovation Center in Portugal, the team pushes the current technology limitations to meet new challenges and customer needs now and for the future. Suzana earned a degree in Electrical Engineering from the University of Saint Cyril and Methodius in Skopje, Macedonia

Suzana Jankuloska is a Product Manager for Electrolytic Capacitors in the Americas. She has been with KEMET since 2012. She is an enthusiast of market and technology trends specifically those requiring high voltage electrolytic capacitors. Working closely with the KEMET Innovation Center in Portugal, the team pushes the current technology limitations to meet new challenges and customer needs now and for the future. Suzana earned a degree in Electrical Engineering from the University of Saint Cyril and Methodius in Skopje, Macedonia

Leave a Reply