Now in its sixth year, Design World’s LEAP Awards continue to showcase the best engineering innovations across several design categories. It’s a large undertaking that wouldn’t be possible without the commitment and support of the engineering community.\

Each year, the editorial team assembles OEM design engineers and academics to create an independent judging panel. Below is their selection for this year’s LEAP Awards winners in the Power Electronics category.

Congratulations to the winners of LEAP Awards for Power Electronics profiled here.

Gold

on Semiconductor

M3S EliteSiC

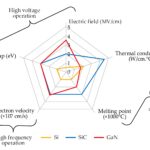

Housed in industry-standard gel-filled module packages, the M3S EliteSiC MOSFET portfolio includes the latest generation M3S EliteSiC MOSFETs and modules that facilitate higher switching speeds to support the growing number of electric vehicle (EV), on-board charger (OBC) and energy infrastructure applications such as EV charging, solar, and energy storage systems.

Housed in industry-standard gel-filled module packages, the M3S EliteSiC MOSFET portfolio includes the latest generation M3S EliteSiC MOSFETs and modules that facilitate higher switching speeds to support the growing number of electric vehicle (EV), on-board charger (OBC) and energy infrastructure applications such as EV charging, solar, and energy storage systems.

In addition, EliteSiC M3S devices in half-bridge power integrated modules (PIMs) offer the industry’s lowest Rds(on) in half-bridge configuration in a standard F2 package. Targeting industrial applications, the modules are ideally suited to DC-AC, AC-DC, and DC-DC high-power conversion stages.

The automotive-qualified 1200 V EliteSiC MOSFETs are tailored for high-power onboard chargers (OBCs) up to 22 kW and high voltage to low voltage DC-DC converters. M3S technology has been developed specifically for high-speed switching applications and has the best-in-class figure of merits for switching losses.

In addition to the trend towards 800V main battery packs, there is a parallel trend of increasing the power capability of the OBC. Units in the 6.6kW range were common in the past. Now many designs are 11kW (split phase mains) and 22kW (three phase mains). While this power level is often not supportable in the home, it is at the more than 126,000 AC charging stations currently available in the US. A higher power OBC can allow faster charge times while at work or in many public spaces, negating the need to establish a full charge while at home. As OBC power levels increase, the advantages of silicon carbide (SiC) MOSFETs also increases.

Enhancing the efficiency of electric vehicles and energy infrastructure applications, the 1200V EliteSiC MOSFETs in discrete packages are tailored for high-power OBCs up to 22 kW, EV charging stations up to 40kW and high voltage to low voltage DC-DC converters. 1200V M3S technology has been developed specifically for high-speed switching applications with optimized Cgs capacitance for lower switching losses, enabling best-in-class figure of merits for switching losses.

Silver

Microchip

Hybrid Power Drive Module

The Microchip Hybrid Power Drive Module (HPD) is used to replace the traditional hydraulic actuation system with electrical actuation systems in airplanes, multi-copters, E-VTOLs& drones to reduce footprints, weight, design complexities and enhance reliability.

The Microchip Hybrid Power Drive Module (HPD) is used to replace the traditional hydraulic actuation system with electrical actuation systems in airplanes, multi-copters, E-VTOLs& drones to reduce footprints, weight, design complexities and enhance reliability.

The integrated HPD module solution reduces the SKU contents/part count, improves time-to-market, provides better configurability, improves reliability (less components/subsystem means better reliability/MTBF), enhances ruggedness, minimizes size/weight of the overall system, and provides cost efficiency.

The HPD510 is an integrated power semiconductor module and gate driver board, and the PCM510 is integrated with a power semiconductor module, gate driver board, and controller, which demonstrated the capability of providing electrical actuation motor drive solutions with additional functionality such as solenoid drive and digital communications to provide a fully-integrated, intelligent motor drive solution. This experience was used to develop more standardized and configurable products like the new HPD power module for aviation applications.

The key differentiators are the integration of a three-phase inverter, brake chopper, soft start circuit, solenoid drive, shunt resistors, and internal thermistors for temperature monitoring— the all-in-one solution also offers various configurations, ease of use, design flexibility (SiC and IGBT power switches), compactness, high reliability, ruggedness, and application expertise backed by experience in providing cost-effective solutions to aviation and defense applications.

Bronze

Power Integrations

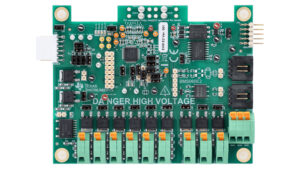

1SP0635V2A0D gate driver

The 1SP0635V2A0D single-channel, plug-and-play gate driver for 190 mm x 140 mm IHM and IHV IGBT modules up to 3300 V is designed for hi-rel applications, including rail traction inverters, power grid, and medium-voltage drives. A key feature is the ability to report telemetry data for observability, predictive maintenance, and lifetime modeling, ensuring that reliability and lifetime is maximized. Research from Siemens Mobility shows that significant cost savings can be achieved using system reporting that facilitates Predictive Maintenance and Lifetime Modeling. Unscheduled stops are reduced by 30%, and maintenance is reduced by 15%. And systems are available 100% of the time.

The 1SP0635V2A0D single-channel, plug-and-play gate driver for 190 mm x 140 mm IHM and IHV IGBT modules up to 3300 V is designed for hi-rel applications, including rail traction inverters, power grid, and medium-voltage drives. A key feature is the ability to report telemetry data for observability, predictive maintenance, and lifetime modeling, ensuring that reliability and lifetime is maximized. Research from Siemens Mobility shows that significant cost savings can be achieved using system reporting that facilitates Predictive Maintenance and Lifetime Modeling. Unscheduled stops are reduced by 30%, and maintenance is reduced by 15%. And systems are available 100% of the time.

These gate drivers employ sophisticated monitoring and protection systems to ensure that hi-rel applications are supported by the most rugged gate drivers available. As a result, failures are reduced to an absolute minimum. Multiple sensing circuits, including thermal and device and bus condition information, are incorporated, simplifying system design and enhancing observability, control, and reliability. High-reliability application areas include rail traction inverters, power grid, and medium-voltage drives.

Telemetric data available from the 1SP0635V2A0D gate driver includes accurate temperature measurement, which simplifies thermal management and eliminates the need for external temperature sensors. DC link voltage measurement is also incorporated, minimizing external circuitry, and reducing system complexity and cost. Closed-loop gate voltage, gate status, and short-circuit monitoring ensure that modules are operated within set limits, improving efficiency and avoiding catastrophic failures.

The serial status output protocol incorporates critical real-time measurements, facilitating advanced operational verification and dramatically increasing the overall visibility of the inverter’s health, reliability, and efficiency. Engineers may adapt monitoring and control systems to the PI standard plug-and-play protocol or request custom adjustments by PI engineers during their project’s development phase.

Other features include a status monitor for the fiber-optic interface to ensure that switching commands are received correctly. Similarly, gate monitoring ensures switching commands have been executed correctly and that the power module is in the appropriate operating condition. Short-circuit monitoring provides accurate control, directing the gate driver to respond appropriately in the event of a short circuit.

Honorable Mention

Texas Instruments

BQ79718-Q1 battery cell monitor and BQ79731-Q1 battery pack monitor for battery management systems

The BQ79731-Q1 and BQ79718-Q1 devices provide a high level of accuracy and precision in measuring battery voltage, current, and temperature to effectively determine the true range of a vehicle and increase the overall life and safety of the battery pack.

The BQ79731-Q1 and BQ79718-Q1 devices provide a high level of accuracy and precision in measuring battery voltage, current, and temperature to effectively determine the true range of a vehicle and increase the overall life and safety of the battery pack.

The BQ79718-Q1 allows automakers to maximize the true range of their EV with high-performance battery cell voltage measurements down to 1 mV of accuracy. It also provides high-accuracy cell voltage measurements for up to 18s battery modules in high-voltage battery management systems in xEV/EV. The BQ79731-Q1 allows measurement of the battery pack current down to 0.05% accuracy, and the monitor can be used to measure divided-down high voltage nodes in a battery system. It can measure voltage across fuse contactors and check isolation voltage in the battery junction box (BJB) system. These innovations will provide the clearest picture possible to measure accurate state of charge and state of health at the individual cell and pack level, effectively reflecting true remaining mileage and instilling confidence in the battery life of their EV.

An industry-leading voltage and current synchronization (64 µs) enables instantaneous monitoring of battery pack power, providing a real-time snapshot of battery health. This level of synchronization enables electrochemical impedance spectroscopy, which provides vital insight into the cell core temperature, battery aging, and state of charge of the battery.

An industry-leading voltage and current synchronization (64 µs) enables instantaneous monitoring of battery pack power, providing a real-time snapshot of battery health. This level of synchronization enables electrochemical impedance spectroscopy, which provides vital insight into the cell core temperature, battery aging, and state of charge of the battery.

For the complete list of 2023 LEAP Award winners across all categories, visit https://www.designworldonline.com/2023-leap-awards-winners-are-announced/.

Leave a Reply