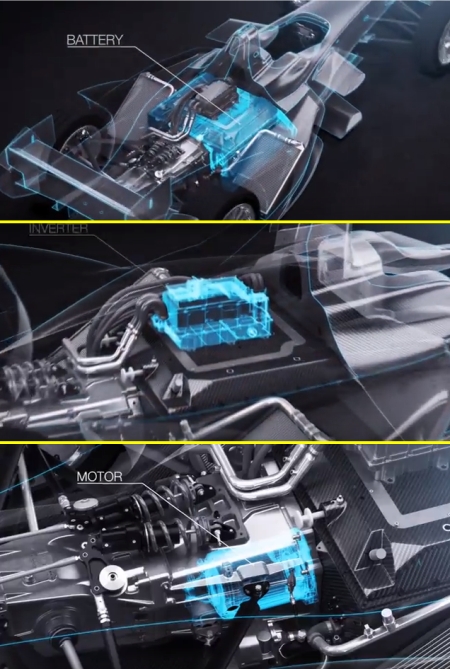

Full SiC power modules will form the basis of the inverter on the Venturi Formula E team in the FIA Formula E 2017–2018 (season four). The racing season will start on December 2nd and 3rd in Hong Kong.

The SiC power modules were devised by ROHM. The inverter for season four features embedded full SiC Power module, making it 43% smaller and 6-kg lighter than the inverter for season two. Compared to the previous inverter used in season three, it is 30% smaller and 4-kg lighter.

The SiC power modules were devised by ROHM. The inverter for season four features embedded full SiC Power module, making it 43% smaller and 6-kg lighter than the inverter for season two. Compared to the previous inverter used in season three, it is 30% smaller and 4-kg lighter.

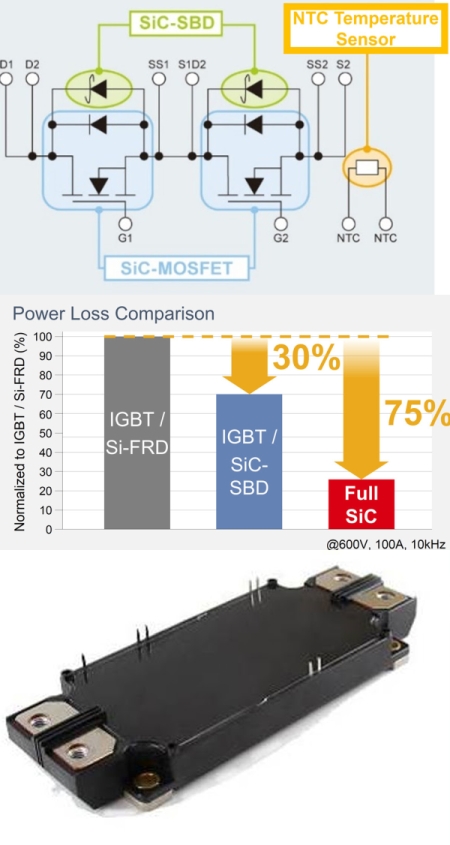

The SiC power module used in the Venturi inverter has new package with an improved internal module structure, as well as optimized thermal management. ROHM says compared to conventional IGBT modules with similar current ratings, this module reduces switching losses by 75% (at a chip temperature of 150°C). This contributes to the energy efficiency for the whole application. Also, having more compact peripheral components throughout the high-frequency drive, as well as the effect of reductions in switching losses, contributes to a more compact cooling system as well.

The SiC power module used in the Venturi inverter has new package with an improved internal module structure, as well as optimized thermal management. ROHM says compared to conventional IGBT modules with similar current ratings, this module reduces switching losses by 75% (at a chip temperature of 150°C). This contributes to the energy efficiency for the whole application. Also, having more compact peripheral components throughout the high-frequency drive, as well as the effect of reductions in switching losses, contributes to a more compact cooling system as well.

Says Kazuhide Ino, ROHM Group General Manager of Power Device Production Headquarters, “We provided SiC-SBDs in season three last year (2016–2017), but this

year we provide full SiC power modules that combine a SiC SBD and a SiC MOSFET. These modules will contribute to improve vehicle performance. I hope that we can continue to contribute to society through the efficient conversion of energy in a wide range of industries and fields, starting with electric vehicles.”

An average Formula E racer has a power of at least 250 hp (190 kW). The race cars are typically able to accelerate from 0–100 km/h (0–62 mph) in three seconds, with a maximum speed of 225 km/h (140 mph).

The first season of Formula E racing had all teams using cars designed by Spark Racing Technology around a chassis from Dallara. Since the second season, regulations permit teams to use other suppliers for the electric motor, inverter, gearbox and cooling system. The chassis and battery stay the same. Nine manufacturers are creating powertrains for the 2016–17 season. Besides Venturi, powertrain suppliers consist of ABT Schaeffler, Andretti Technologies, DS-Virgin, Jaguar, Mahindra, NextEV TCR, Penske, and Renault.

Leave a Reply