Formula E is an all-electric-powered FIA (Fédération Internationale de l’Automobile) championship that began in 2014. In 2018, ABB is brought its name to the series, which is now known as the “ABB FIA Formula E Championship.” The races are set to 45 minutes plus one lap. During the first four seasons, drivers made one mandatory pit stop to change cars. With Gen2 cars, the car change is no longer necessary because the battery lasts for the full race. Pit stops are currently limited to changing a flat tire or performing repairs on the car (that will change in a couple of years with Gen3 cars when there will be a mandatory battery charging pit stop, more on that in Part 2 of this FAQ series).

The fifth season of Formula E (2018-2019) saw the introduction of Gen2 cars. As was true for Gen1 cars, Gen2 shares a car body and a standard battery pack. While that limits innovation in two areas, it incentivizes race teams to seek competitive advantage in other areas, for example, in motor and inverter designs.

Battery upgrades were a major focus on Gen2 changes. Gen1 battery specifications included a 200 kg (440 lb) cell-weight limit, a 200kW peak power limit, and maximum usable energy of 28kWh. The 28kWh was a major limitation and made a mid-race car change necessary.

For Gen 2, the battery weight increased to 250 kg (551 pounds), peak power went up to 250kW, and the energy nearly doubled to 54kWh, enabling a car to complete the entire race on a single charge and eliminating the need for two cars per driver.

In Gen2, the lithium polymer pouch cells used in the Gen1 battery pack were replaced with 18650VTC6 cylindrical Li-ion cells from Murata. The 18650VTC6 is optimized to deliver high power and has a volumetric energy density of 631Wh/L, a gravimetric energy density of 241Wh/kg, and a continuous discharge rating of 30 Amps. Gen2 cars are not designed to be charged during the race; the teams do charging before the race begins.

The larger Gen2 battery pack not only enables cars to complete the race on a single charge, but it also provides more power; 250kW of power during qualifying and up to 220kW during the race. With 220kW available, top racing speeds have been increased by 24% from 225 kph to 280 kph (or from 140 mph to 174 mph). While Gen2 cars are capable of 280 kpm, there are no straights on the current Formula E schedule long enough to achieve that speed. Acceleration also increased. Gen1 cars needed about 3.5 seconds to go from 0 to 100 kph while Gen2 cars achieve 100 kph in 2.8 seconds.

The bigger battery pack weighs more, but the rest of the car has lost weight. While the battery pack weight increased by 65 kg from 320 kg to 385 kg (from 705 lbs to 848 lbs), the overall weight of the car has only increased by 20 kg, from 880 kg to 900 kg (1940 lbs to 1984 lbs).

Attack mode and FANBOOST

Also, with Gen2, a feature called Attack Mode was introduced in which drivers receive an additional 25kW of power for up to 8 minutes by driving through a designated area of the circuit off the racing line. The duration of the boost mode and the number of boosts available are decided only shortly in advance of each race by the FIA to stop teams from anticipating its use and incorporating it into race strategy.

All attack modes must be activated at the end of the race but do not need to be used up (i.e., if a final attack mode is activated in the penultimate lap, the driver is not penalized for having it still activated at the end of the race.) In the recently ended season 6, the additional power was increased to 35 kW.

In addition, an LED display (“Halo”) has been added on the outside of the cars so fans can see how much power each car has. The lighting on the Halo glows magenta (when the driver has engaged Attack Mode) and blue (when the car is in Race Mode), enabling fans to follow the strategy of each team and driver.

Formula E is the only event in the world that lets fans play an active role in influencing the outcome of the race. FANBOOST gives fans the opportunity to vote for their favorite driver and award them an extra boost of power in a 5-second window during the second half of the race.

Brake by wire and regenerative braking

A new brake-by-wire system has been added in Gen2. In past seasons, when the driver used the brakes, they got both the deceleration from the brakes themselves and a varying amount of slowing from the regenerative braking effect (regen) on the rear wheels. Although the driver could adjust the regen settings from the steering wheel, they could still be caught out by a change in braking effort, causing them to lock up or spin.

Now, with the brake-by-wire system (BBW), this only affects the rear brakes. The driver presses the brake pedal as usual. Then the electronic control unit (ECU) balances how much braking the driver wants and what braking effect will be supplied by the regen. The ECU then only applies the rear brakes enough to balance the two. This gives a balanced and consistent braking effect for the driver.

The increase in weight of the cars, and the ability of the cars to go faster, put greater demands on the braking system. Plus, the new braking system must last the entire race, not just half the time, as was true for Gen1 cars. Gen2 carbon brake pads and disks are thicker and have more ventilation compared with the Gen1 brake system. With the new system, teams are allowed to fit brake ducts to the front brakes for the first time, to tailor brake cooling to suit specific track conditions.

Better motors and inverters make better racecars

Teams can use their own motor designs homologated with the FIA or may procure one from an existing manufacturer with an FIA homologated design. In either case, the cost can be no more than €250,000.

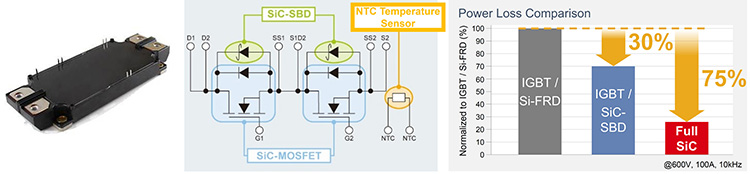

For the first two seasons, Gen1 motor drive inverters were designed using IGBT modules that included silicon fast recovery diodes (FRDs). More recently, silicon carbide (SiC) power devices have been incorporated into Formula E motor drives. For example, ROHM became VENTURI’s official technology partner in season 3 and supplied IGBT modules that replaced the silicon FRDs with SiC Schottky barrier diodes (SBDs). The inverter for season 4 featured an embedded full SiC Power module, making it 43% smaller and 6kg lighter than the inverter for season two. Even compared to the previous inverter used in season three, it is 30% smaller and 4kg lighter.

In another example of drivetrain innovation, ZF Friedrichshafen AG is the new “Official Powertrain Partner” of Mahindra Racing, one of the founding teams in the ABB FIA Formula E Championship. Together with Mahindra Racing, ZF has started development of the electric driveline for the 2020/2021 season. In addition to the electric motor, the development includes both a single-gear, highly efficient transmission, and SiC-based power electronics, which have been specifically designed for the application in motorsports.

Software can be THE difference-maker

The electric motor, gearbox, and powertrain units are developed and refined several months prior to the start of the season, then they are homologated, and the designs are frozen. Any change in the design brings a penalty. Software is different; it can be updated throughout the season, enabling teams to continue learning and improving the control systems of the car to make it faster and more efficient. Software has been called the “new aerodynamics.” And it controls everything from the drivetrain to the battery and energy systems. Formula E racing is as much about energy management as it is about speed.

For example, Envision Virgin Racing has teamed up with Genpact to enhance its race performance and drive innovation in sustainable electric cars. A key part of the partnership will be using AI and machine learning to analyze the huge amounts of data and assess race performance patterns that will enable the team to identify new racing strategies. The new rules that are coming to Formula E mean that every second of a race brings a new crucial decision. Combining deep analytics with car telemetry data feeds from more than a hundred sensors will help the team improve its pre-race strategy simulations and models that lead to more informed race day decisions.

And, TAG Heuer Porsche Formula E Team has a collaboration with ANSY. Porsche Motorsport engineers are using ANSYS’ industry-leading system-level simulation solutions to create an advanced electric powertrain that will substantially increase energy efficiency for Porsche’s first-ever fully-electric race car — the Porsche 99X Electric. Accelerating at extreme speeds through demanding urban courses within metropolitan city centers exerts massive stresses on the powertrain of the Porsche 99X Electric. While regulations stipulate a standardized chassis and battery, engineers can customize the powertrain and its subsystems and components to deliver maximum energy efficiency and vehicle performance from the starting line to the finish line.

The next FAQ in this three-part series will look at “Formula E Gen3 Smaller Batteries, Regen and Fast Charging.”

References:

ABB Formula E, ABB FIA Formula E Championship

Formula E, Wikipedia

ROHM supplies Full SiC Power Modules to Formula E racing team Venturi, ROHM

Six Things You Didn’t Know About Formula E, Williams Advanced Engineering

Leave a Reply