A multiphase, interleaved buck converter can reduce bus voltage down to something useful in data center server racks.

Brad Xiao, Nazzareno (Reno) Rossetti Maxim Integrated

Hyperscale data centers that dissipate hundreds of megawatts demand efficient power delivery beyond the ability of the traditional 12-V power supplies on old server motherboards. A data center on 12 V has a power usage effectiveness (PUE) of 1.1 at best. It wastes 10% of its power (tens of megawatts) on cooling and overhead. That wasted power could comfortably supply electricity to a small city with about 10,000 homes.

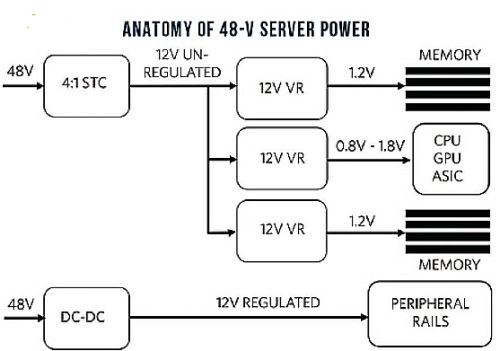

The move from 12 to 48-V power brings several advantages. The server rack dissipates heat more efficiently, costs less, and can be smaller as a consequence of the reduced current (4x), copper losses (16x), and connector/bus bar sizing. In the power management architecture of a modern data center, different strategies are adopted to power different classes of loads like processors, memories, and peripherals. Peripherals such as PCIE and HDDs require a 12-V supply rail. One way to get the required 12 V is through use of a multiphase, interleaved, coupled-inductor-based 48-to-12-V step-down converter. This converter design is compact, efficient, and cost-effective.

The best strategy to power low-voltage (< 1.8 V), high-current loads like memories and microprocessors is to reduce the 48 V down to an unregulated 12-V rail. An open-loop, unregulated 4:1 switched-tank converter (STC) topology enables soft-switching operation with peak efficiency in the 98% to 99% range. From here, high-efficiency 12-V voltage regulator-converters power the various loads. Peripherals like PCIE and HDDs require a 12-V supply rail and currents up to 100 A (1.2 kW). In this case, a 48-to-12-V regulated, interleaved, multiphase dc-dc converter can do the job.

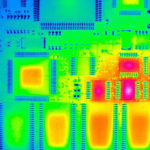

Use of a four-phase interleaved dc-dc converter reduces ripple current and, hence, ripple voltage, compared to that of a single-phase converter. Lowering output current ripple and voltage ripple means fewer capacitors on the output, resulting in a smaller BOM. The four-phase architecture also requires fewer input capacitors.

The total input current is the sum of the four out-of-phase currents. Here, spreading the total input current over time reduces the total RMS value of the input current compared to that of a single-phase setup. This spreading makes possible a smaller input current-ripple filter. Another great benefit of a four-phase converter is a fast transient response and lower voltage overshoot/undershoot during load steps. Lower overshoots, in turn, allow a tighter voltage rail powering the electronic load with less headroom needed for transient droop, resulting in less power dissipated at the load.

Additional efficiencies can be had through use of a coupled inductor in which the inductor coils wind around a common magnetic core. Here, the winding orientation is such that the magnetic flux cancels out, resulting in less than a quarter of the ripple current compared to that of four uncoupled inductors. Extremely low ripple current yields the smallest BOM and highest efficiency.

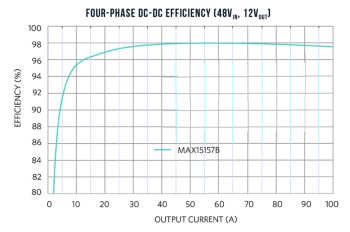

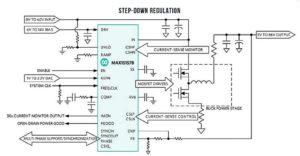

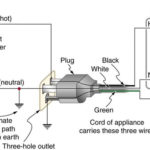

An example of a device that makes possible efficient 48-to-12-V conversion is the 8-to-60-V MAX15157B fixed-frequency, current-mode PWM controller. It drives two power MOSFETs in a buck configuration, synthesizing a 48-to-12-V step-down regulator. Four ICs–in conjunction with external discrete MOSFETs, capacitors, and a single coupled inductor–are interleaved for multi-phase operation. The switching frequency is controlled either through an external resistor setting the internal oscillator frequency or by synchronizing the regulator to an external clock. The device is designed to support switching frequencies ranging from 120 kHz to 1 MHz. Each IC is available in a 5×5-mm, 32-pin TQFN package and supports a -40 to +125°C junction temperature range. In a four-phase, coupled-inductor configuration, this topology yields an outstanding 97.9% peak and 97.43% full-load efficiency (12 V, 100 A, 1.2 kW).

The 48-to-12-V PCB layout with a coupled inductor can easily sit on the data server motherboard. It fits in a quarter-brick size on one side of a PCB and in an eighth-brick form factor on two PCB sides.

In a nutshell, high levels of efficiency available through use of such 48-to-12-V conversion techniques offer a path toward power usage effectiveness approaching unity in a not-so-distant future.

Leave a Reply