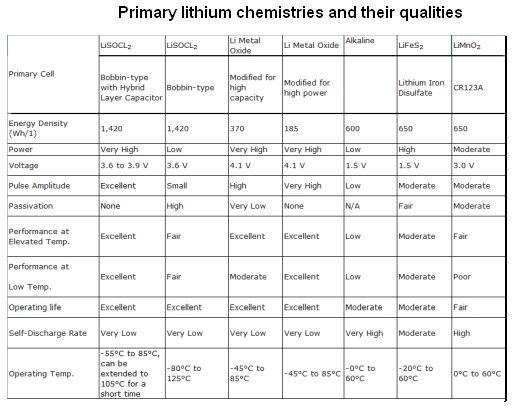

Battery chemistries each have special qualities that can make certain cells impractical for varying kinds of internet-of-things applications.

Sol Jacobs | Tadiran Batteries

Circuit designers often find themselves in the position of trying to squeeze as much life as possible out of a battery. Today there is much discussion about boosting battery life through use of low-power chipsets or more efficient communication protocols. But the potential savings available do not make up for the loss of operating life arising from battery self-discharge.

Long-life batteries help reduce the total cost of ownership by powering low-power devices maintenance-free for up to 40 years, demanding incredibly low battery self-discharge.

Long-life lithium batteries

Many Industrial Internet of Things (IIoT) devices use two-way wireless communications. This wireless connectivity allows big-data analytics and artificial intelligence (AI) to enhance workflow, make people more productive, and companies more profitable. Remote wireless devices connected to the IIoT commonly require industrial-grade lithium batteries that deliver reliable, long-term power to remote locations and challenging environments.

A prime example is in the modern oil refinery, which is equipped with an average of 30,000 sensors, many of which are interoperable using the decades-old HART (Highway Addressable Remote Transducer) protocol. Unfortunately, the majority of HART-enabled devices were never fully integrated because the cost of hard-wiring is prohibitive, estimated at roughly $100/ft for any type of hard-wired device, even a basic electrical switch. And wiring costs can be much higher in remote locations and extreme environments. Fortunately, the development of the WirelessHART protocol has eliminated the costs associated with hard-wiring.

A remote wireless device drawing just microwatts of energy which must have a long operating life will likely be powered by an industrial-grade primary (non-rechargeable) lithium battery. Conversely, a device drawing average daily current in the milliamp range could deplete a primary battery quickly. Here, it may be better to employ some form of energy harvesting device combined with a lithium-ion (Li-ion) rechargeable battery able to store the harvested energy.

Remote industrial wireless applications are rarely powered by consumer-grade alkaline batteries. These cells suffer from high annual self-discharge rates that exhaust the cell capacity in a few years or less. Alkaline batteries also employ a water-based chemistry that is prone to freezing, making them ill-suited for extreme environments. Although inexpensive, consumer-grade alkaline batteries can make overall costs higher when the recurring expenses associated with replacing batteries are factored in.

How to choose an industrial-grade battery

The process of selecting an industrial-grade lithium battery starts with prioritizing the most important technical requirements including: the amount of current consumed in active mode (along with the size, duration, and frequency of pulses); energy consumed in stand-by or sleep mode (the base current); storage time (as normal self-discharge during storage diminishes capacity); expected temperatures (including during storage and in-field operation); equipment cut-off voltage (as battery capacity is exhausted, or in extreme temperatures, voltage can drop to a point too low for the sensor to operate); the annual self-discharge rate of the battery (which can approach the amount of current drawn from average daily use).

Key considerations include:

Reliability – Is the remote wireless device going into an inaccessible spot where battery replacement is difficult or impossible and loss of data caused by battery failure is unacceptable?

Long operating life – Does the self-discharge rate of the battery approach or exceed the average daily energy consumption? If so, the application calls for a high-capacity battery.

Miniaturization – Batteries with high capacity and high energy density support a smaller footprint.

Extended temperatures – Certain lithium battery chemistries can operate in extreme temperatures without a significant rise in their self-discharge rate.

Higher voltage – Specifying batteries with higher voltage may enable the use of fewer cells.

Lifetime costs – Determining your true cost of ownership must include all expenses related to future battery replacements, along with the risks associated with battery failure.

Lithium batteries are preferred for long-term deployments because of their high intrinsic negative potential, which exceeds that of all other metals. As the lightest non-gaseous metal, lithium offers the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of all available battery chemistries. Lithium cells operate within a normal operating current voltage (OCV) range of 2.7 to 3.6 V. The fact they contain no water also allows lithium batteries to endure extreme temperatures without freezing.

Numerous primary lithium chemistries are available including iron disulfate (LiFeS2), lithium manganese dioxide (LiMNO2), lithium thionyl chloride (LiSOCl2), and lithium metal-oxide chemistry.

Numerous primary lithium chemistries are available including iron disulfate (LiFeS2), lithium manganese dioxide (LiMNO2), lithium thionyl chloride (LiSOCl2), and lithium metal-oxide chemistry.

LiFeS2 cells are relatively inexpensive and typically are deployed to deliver high pulses to power a camera flash. LiFeS2 batteries have performance limitations that include a narrow temperature range (-20 to 60°C), a high annual self-discharge rate, and crimped seals that may leak.

LiMNO2 cells, including the widely used CR123A, are commonly used to save space in cameras and toys, as one 3-V LiMNO2 cell can replace two 1.5-V alkaline cells. LiMNO2 batteries can deliver moderate pulses but have limitations such as low initial voltage, a narrow temperature range, a high self-discharge rate, and crimped seals.

LiSOCl2 batteries can be constructed two ways: bobbin-type and spiral wound. Bobbin-type LiSOCl2 batteries exhibit a low annual self-discharge and are thus preferred for long-term deployments that use low average daily current including AMR/AMI metering, M2M, SCADA, tank-level monitoring, asset tracking, environmental sensors, and extreme temperature applications.

Bobbin-type LiSOCl2 batteries feature the highest capacity and highest energy density of any lithium cell, along with an extremely low annual self-discharge (under 1% per year for certain cells), thus permitting up to 40-year battery life for certain applications. Bobbin-type LiSOCl2 batteries also deliver the widest possible temperature range (-80 to 125°C) and feature a superior quality glass-to-metal hermetic seal.

Bobbin-type LiSOCl2 batteries feature the highest capacity and highest energy density of any lithium cell, along with an extremely low annual self-discharge (under 1% per year for certain cells), thus permitting up to 40-year battery life for certain applications. Bobbin-type LiSOCl2 batteries also deliver the widest possible temperature range (-80 to 125°C) and feature a superior quality glass-to-metal hermetic seal.

Specially modified bobbin-type LiSOCl2 batteries can be adapted for use in the cold chain, where wireless sensors monitor the transport of frozen foods, pharmaceuticals, tissue samples, and transplant organs at temperatures as low as -80°C. Bobbin-type LiSOCl2 batteries can also handle extreme heat. For example, these cells have served in active RFID tags that track the location and status of medical equipment without having to remove the battery prior to autoclave sterilization, where temperatures can reach 125°C.

Be aware that the annual self-discharge rate of bobbin-type LiSOCl2 batteries may vary significantly based on their method of manufacture and the quality of the raw materials. For example, a top-quality bobbin-type LiSOCl2 cell can have an annual self-discharge rate as low as 0.7%, retaining over 70% of its original capacity after 40 years. By contrast, a lower quality bobbin-type LiSOCl2 cell can have a self-discharge rate of up to 3% per year. While this difference may not seem overly significant, it really adds up. A lower-quality cell can lose up to 30% of its available capacity every 10 years, eliminating the possibility of a 40-year battery life.

The impact of a higher self-discharge rate may not become apparent for years, and theoretical test data can be highly misleading. Thorough due diligence is a must if the application demands long-life power, especially in extreme environments. Ask all potential battery suppliers to provide fully documented long-term test results and in-field performance data from similar applications, along with customer references.

For example, it pays to choose the cell with the lowest annual self-discharge rate when specifying a long-life bobbin-type LiSOCl2 battery for meter transmitter units (MTUs) in AMR/AMI utility metering applications. Here, a large-scale battery failure can disrupt customer billing systems and disable remote service start-up and shut-off capabilities. The possibility of such wide-scale chaos could force a utility to prematurely invest millions of dollars to replace batteries early so as not to jeopardize data integrity.

High pulses

The IIoT includes numerous remote wireless devices that require periodic high pulses to power advanced two-way wireless communications. A standard bobbin-type LiSOCl2 battery cannot deliver high pulses because of its low rate design, but it can easily be combined with a

patented hybrid layer capacitor (HLC) to support such needs. The standard bobbin-type LiSOCl2 cell delivers low daily background current while the HLC handles periodic high pulses. The patented HLC also features a special end-of-life voltage plateau that can be interpreted and programmed to deliver low-battery status alerts.

Many consumer electronic products employ supercapacitors which deliver high pulses electrostatically rather than chemically. Supercapacitors have inherent limitations that keep them out of industrial applications. These include their short-duration power, linear discharge qualities that prevent use of all the available energy, low capacity, low energy density, and high annual self-discharge rates (up to 60% per year). Supercapacitors linked in series also require the use of cell-balancing circuits, which add to cost and bulkiness and consume energy to reduce their shelf-life.

High pulses invariably draw additional current, so intelligent energy management requires techniques such as using a low-power communications protocol (ZigBee, WirelessHART, LoRa, etc.), low-power microprocessors, and other techniques to minimize the amount of energy consumed during data interrogation and transmission.

A growing number of wireless IIoT applications are good candidates for combining energy harvesting devices with Li-ion rechargeable batteries, especially applications that draw enough average daily current (milliamps) that would quickly exhaust a primary lithium battery. One prime example is a solar-powered tracking device that continuously monitors the health of animal herds. Another example is a solar-powered parking meter that automates billing and fee collection while also identifying open parking spots to reduce pollution and traffic congestion.

Photovoltaic (PV) panels are the most proven form of industrial energy harvesting. Energy can also be harvested from equipment movement or vibration, temperature variances, and ambient RF/EM signals.

Consumer-grade rechargeable Li-ion cells may work if the device is easily accessible, needs an operating life of just five years and 500 recharge cycles, and operates within a moderate temperature range (0 – 40°C), with no high pulse requirements. However, industrial-grade rechargeable Li-ion batteries work best for long-term deployment in a remote location or extreme environments, and/or if high pulses are required.

Industrial grade Li-ion batteries can lower the cost of ownership by operating maintenance-free for up to 20 years and 5,000 full recharge cycles, with an expanded temperature range of -40 to 85°C, delivering the high pulses powering two-way wireless communications. These ruggedly constructed cells feature a hermetic seal that delivers superior safety protection not found in consumer-grade rechargeable Li-ion batteries.

Leave a Reply