Hosted by Jeff Shepard, EE World has organized this “virtual roundtable” into “X and Y Safety Capacitor Applications” with Eduardo Drehmer (ED), Director of Marketing for Film Capacitors & Power Quality Solutions with TDK Electronics, Inc. and Daniel West (DW), Field Application Engineer with AVX Corp.

JS: What are the most confusing aspects of X and Y safety capacitor specifications for designers?

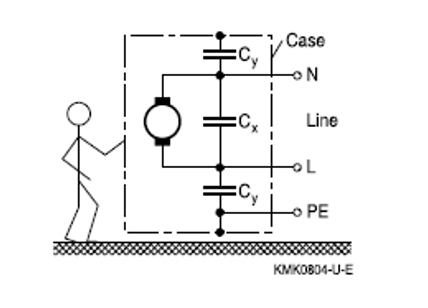

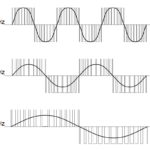

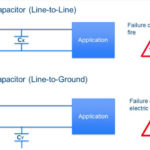

ED: Their main difference is in the level of safety they provide. X capacitors are required for connections between mains or neutral. Y capacitors are required whenever there is a connection to grounded nodes. Due to the fact that equipment cases are usually grounded, Y caps require higher safety to avoid risks of electrical shocks to users. Here is some interesting info on this:

DW: Keeping up with classifications and certifications, knowing where they should go and which are interchangeable can be very confusing for designers. In addition, there are multiple capacitor technologies to consider, all with varying lists of features and benefits.

JS: When is it most appropriate to use ceramic capacitors versus film capacitors as X and Y safety capacitors?

DW: Some characteristics to consider would be the temperature profile over the life of the application, size constraints, and maybe even cost or ease of assembly. Ceramics can achieve higher capacitance values in a smaller volume, while the film has a self-healing feature inherent in the technology.

ED: Ceramic safety caps are usually preferred for low power applications due to their reduced size, but higher capacitance value safety caps are only found in film technology.

JS: What are the most important design considerations and industry standards that apply to safety capacitor use?

ED: The industry follows several standards, the most common are:

However, the market for stringent applications has been defining requirements beyond the ones found by these standards. That is why it’s very important that designers understand the limitations of the components they are using.

However, the market for stringent applications has been defining requirements beyond the ones found by these standards. That is why it’s very important that designers understand the limitations of the components they are using.

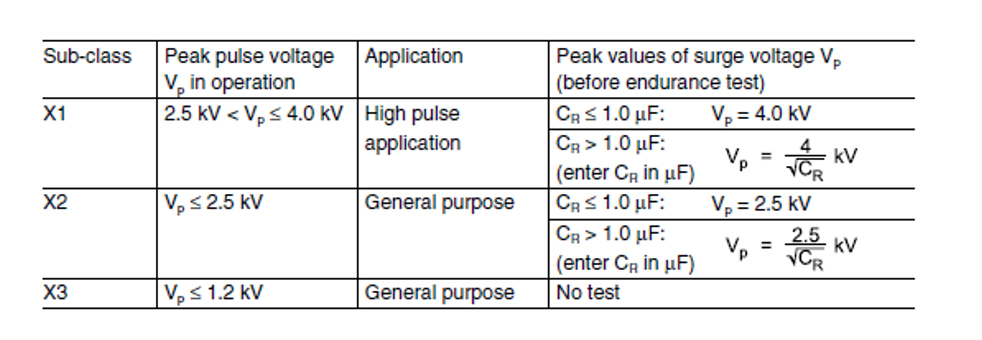

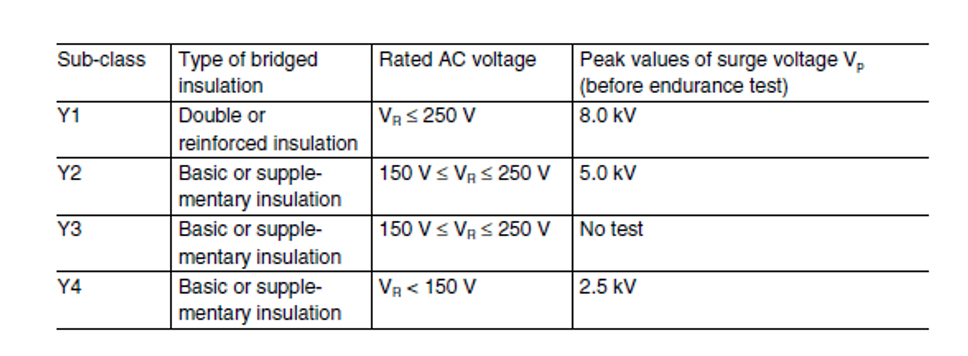

DW: The capacitor class and subclass are very important, it tells the designer what voltages and impulse the capacitor can withstand, in addition to which application it should be used for i.e. across-the-line or line-to-ground. Certifications are also important to confirm IEC 60384-14.4 safety tests.

JS Are there uses for safety capacitors in DC/DC converter applications?

DW: Safety capacitors can be used to isolate the input and/or output if it is referenced back to a non-isolated buck on mains voltages, especially if a user has access to the connections or interface.

ED: Standards require the usage of protection and safety devices for all equipment connected to the grid or to subcircuits. These must be used as input filters and can operate as generic filters through the circuit.

JS: Thanks to our panelists for sharing their insights and experience! You might also be interested in reading “Output Filter Capacitors for Power Converters” Virtual Roundtable (part 2 of 2).

Leave a Reply