For operating and backup power and energy storage, engineers can choose among batteries, supercapacitors, or “best of both” hybrid supercapacitors.

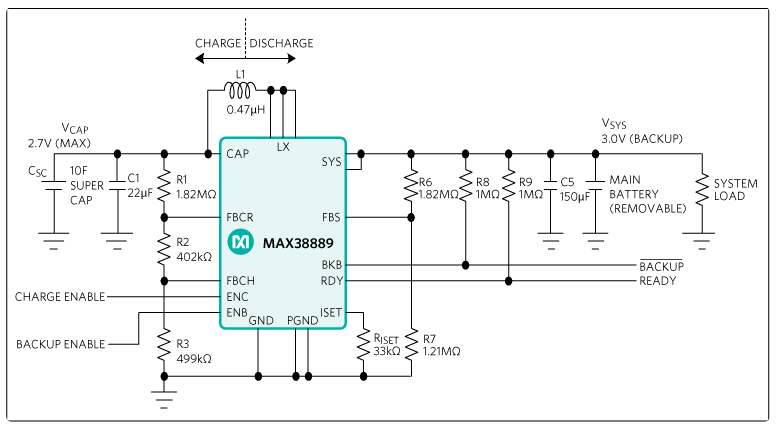

Just as with rechargeable batteries, supercapacitors need proper management to optimize their performance and avoid mishaps. In many ways, the supervisory requirements for both are similar but there are some differences. Vendors of power-management ICs (PMICs) recognize this and have developed devices especially for this situation, such as the Maxim MAX38889 supercapacitor backup regulator (Figure 1).

This IC is designed to transfer power between a supercapacitor and a system supply rail. When the main battery is present and above the minimum system voltage for charging, the MAX38889 charges the supercapacitor. Once the supercapacitor is charged, the circuit maintains the supercapacitor in its ready state. When the main battery is removed, the MAX38889 draws power from the supercapacitor and regulates the system voltage to the set backup voltage.

Going beyond supercapacitors to hybrids

The rechargeable battery and the supercapacitor have many similar functions and applications, but each has a unique set of strengths and weaknesses relative to each other. In many cases, designers would want to employ the best of both, with each overcoming the apparent shortcomings of the other.

The most significant advantage supercapacitors have over batteries is their ability to be charged and discharged continuously without degrading like batteries do. This is why batteries and supercapacitors are used in conjunction with each other. The supercapacitors will supply power to the system when surges or energy bursts since are required. Supercapacitors can be charged and discharged quickly while the batteries can supply the bulk energy since they can store and deliver larger amount energy over a longer slower period of time.

This is actually done by circuit designers, with the use of both a rechargeable battery and a supercapacitor in the same design as shown by the application drawing for the MAX38889. In fact, it would make sense for a vendor to package both devices in a single housing and call it a hybrid device, to simplify the bill of materials (BOM) and possibly save board space.

But that simplistic co-packaging solution still falls short since the so-called hybrid device does not offer any technical benefits beyond the package. Instead, vendors have devised a much better approach which creates a unique energy-storage device which truly is a hybrid supercapacitor. This device combines the features of the battery and the supercapacitor but not by just co-packaging the two devices to look like one.

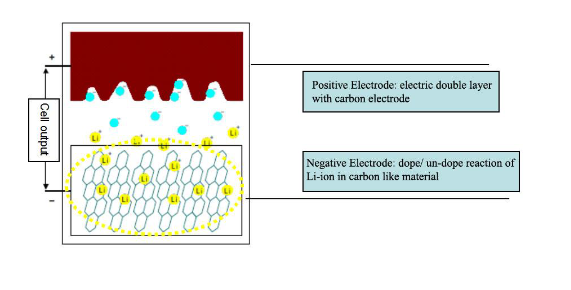

Instead, this true hybrid technology is actually much more complicated, with an internal arrangement which literally merges the materials and principles of the supercapacitor with the lithium-ion rechargeable battery into a single structure (Figure 2). The resultant component is both a battery and a supercapacitor but as a unified device, not as two distinct devices in a single package.

From a construction standpoint, the basic supercapacitor and the hybrid supercapacitor may appear similar, but a hybrid supercapacitor uses an anode made from graphite laced with lithium and a different electrolyte. Each supercapacitor has two electrodes, one similar to that of a battery and one a standard supercapacitor electrode. Consequently, their energy densities are closer to those of conventional batteries and up to 10 times higher than standard supercapacitors.

Among the vendors of these hybrid supercapacitors are Taiyo Yuden (who calls them lithium-ion supercapacitors rather than hybrid supercapacitors, which is technically quite correct), Eaton, and Maxwell Technologies, Inc (now part of Tesla).

Hybrid supercapacitors in other ways from a traditional supercapacitor. They have higher operating voltage (3.8 V maximum) and much higher capacitance and energy density (up to 10 times) than standard symmetric supercapacitors, along with have much lower self-discharge and standby current. On the other side, traditional supercapacitors have higher power capability due to lower ESR (equivalent series resistance), their operating temperature range is broader, and they can be discharged to zero volts for safety while hybrid supercapacitors cannot be discharged fully.

As with all electronic components, performance changes versus temperature are important design considerations. While specifics vary with vendor and model (Figure 3) gives an indication of the ESR and capacitance performance of two hybrid supercapacitor families from one vendor (Eaton) versus temperature. Their HSL supercapacitors are optimized for lower temperatures, going down to -25 °C, while the HS supercapacitors have an extended range to +85 °C and are optimized for higher temperatures.

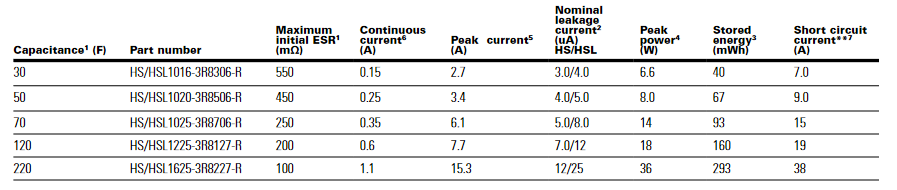

With respect to top-tier parameters, the Eaton HS and HSL hybrid cylindrical cells offer capacitance values between 30 F and 220 F with a maximum working voltage of 3.8 V. Other key specifications related to current, power, and energy for this series are shown in (Figure 4).

Hybrid supercapacitors require a cell management system (CMS) in most cases, similar to but simpler than a battery management system (BMS) associated with lead acid or lithium-ion batteries. With a supercapacitor (standard or hybrid), the management system objective is to maximize the lifetime of the product, whereas battery systems need a management system for safety. The CMS must stop discharging at 2.2 V and to keep the cell voltages equal in designs where multiple cells are connected in series.

Providing operating and backup energy storage and power delivery are critical issues in many designs. Engineers can choose among non-rechargeable and rechargeable batteries, supercapacitors, and even hybrid supercapacitors. The decision involves tradeoffs but viable, compact, hassle-free, and cost-effective options are available.

EE World Related Content

Supercapacitor line now ranges from coin cell, radial form factors, large snap-in types

Supercapacitors operate at 3 and 6 V

What’s new in electrolytic capacitors and supercapacitors for energy harvesting

Supercapacitor system design considerations

Supercapacitor specifications and lifetimes – Virtual Roundtable (part 2 of 2)

Supercapacitor ESR and optimal performance – Virtual Roundtable (part 1 of 2)

Supercapacitor specifications and IEC/EN 62391–1

Supercapacitor operation – a higher power source

Applying large banks of supercapacitors

External References

Wikipedia, “Supercapacitor”

Eaton, “Hybrid supercapacitors explained”

Eaton, “HS Hybrid supercapacitor white paper”

Eaton, “Supercapacitor back up power solutions”

Eaton, “HB Supercapacitors Cylindrical cells” (supercapacitor data sheet)

Eaton, “HS/HSL Hybrid Supercapacitors” (hybrid supercapacitor data sheet)

Battery University (Cadex), “BU-209: How does a Supercapacitor Work?”

Taiyo Yuden, “Lithium Ion Capacitors: The Ultimate EDLC Replacement”

Taiyo Yuden, “Power Storage Devices: Lithium Ion Capacitors;Electric Double-Layer Capacitors”

Tech Briefs, “Supercapacitors Go Hybrid for Increased Performance and Efficiency

Kemet, “Supercapacitors vs. batteries”

Illinois Capacitor, “Supercapacitors”

Basic Electronics 16, “Supercapacitors”

Jinzhou Kaimei Power Co., Ltd. “The Supercapacitors: its Basic Principles, Classification, and its Electrical Performance”

Leave a Reply